%%{init: {'theme':'base', 'themeVariables': {'primaryColor':'#2C3E50','primaryTextColor':'#fff','primaryBorderColor':'#16A085','lineColor':'#16A085','secondaryColor':'#E67E22','tertiaryColor':'#ECF0F1','fontSize':'13px'}}}%%

flowchart TD

Start[Start Sensor Implementation]

Research[1. Research Phase<br/>Datasheet review<br/>Select libraries]

Wire[2. Hardware Setup<br/>Breadboard wiring<br/>Power connections]

Basic[3. Basic Test<br/>Verify communication<br/>Read raw values]

Calibrate[4. Calibration<br/>Two-point calibration<br/>Offset correction]

Filter[5. Data Processing<br/>Noise filtering<br/>Validation checks]

Deploy[6. Deployment<br/>Production code<br/>Error handling]

Check1{Communication<br/>OK?}

Check2{Values<br/>accurate?}

Check3{Stable<br/>readings?}

Debug1[DEBUG: Check wiring<br/>Verify voltage levels<br/>Test I2C scan]

Debug2[DEBUG: Calibrate sensor<br/>Check environmental factors<br/>Review datasheet specs]

Debug3[DEBUG: Add filtering<br/>Check power supply<br/>Shield from noise]

Start --> Research

Research --> Wire

Wire --> Basic

Basic --> Check1

Check1 -->|No| Debug1

Debug1 --> Wire

Check1 -->|Yes| Calibrate

Calibrate --> Check2

Check2 -->|No| Debug2

Debug2 --> Calibrate

Check2 -->|Yes| Filter

Filter --> Check3

Check3 -->|No| Debug3

Debug3 --> Filter

Check3 -->|Yes| Deploy

style Start fill:#2C3E50,stroke:#16A085,color:#fff

style Deploy fill:#27ae60,stroke:#2C3E50,color:#fff

style Research fill:#16A085,stroke:#2C3E50,color:#fff

style Wire fill:#16A085,stroke:#2C3E50,color:#fff

style Basic fill:#16A085,stroke:#2C3E50,color:#fff

style Calibrate fill:#16A085,stroke:#2C3E50,color:#fff

style Filter fill:#16A085,stroke:#2C3E50,color:#fff

style Check1 fill:#E67E22,stroke:#2C3E50,color:#fff

style Check2 fill:#E67E22,stroke:#2C3E50,color:#fff

style Check3 fill:#E67E22,stroke:#2C3E50,color:#fff

style Debug1 fill:#c0392b,stroke:#2C3E50,color:#fff

style Debug2 fill:#c0392b,stroke:#2C3E50,color:#fff

style Debug3 fill:#c0392b,stroke:#2C3E50,color:#fff

531 Temperature Sensor Labs

531.1 Learning Objectives

By the end of this chapter, you will be able to:

- Interface DS18B20 sensors: Configure 1-Wire bus and read multiple temperature sensors on a single pin

- Understand thermocouple fundamentals: Learn how thermocouples generate temperature-dependent voltages

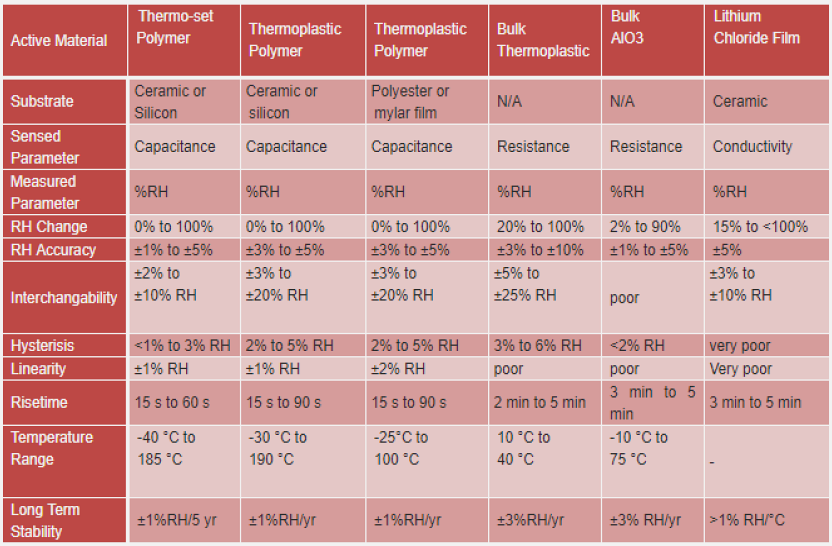

- Compare humidity sensors: Evaluate capacitive, resistive, and thermal conductivity sensing methods

- Implement temperature monitoring: Build robust temperature acquisition systems with proper wiring and pull-up resistors

531.2 Prerequisites

Required Knowledge:

- Sensor Fundamentals - Sensor types and characteristics

- Electronics Basics - Circuit fundamentals

- Sensor Circuits - Signal conditioning

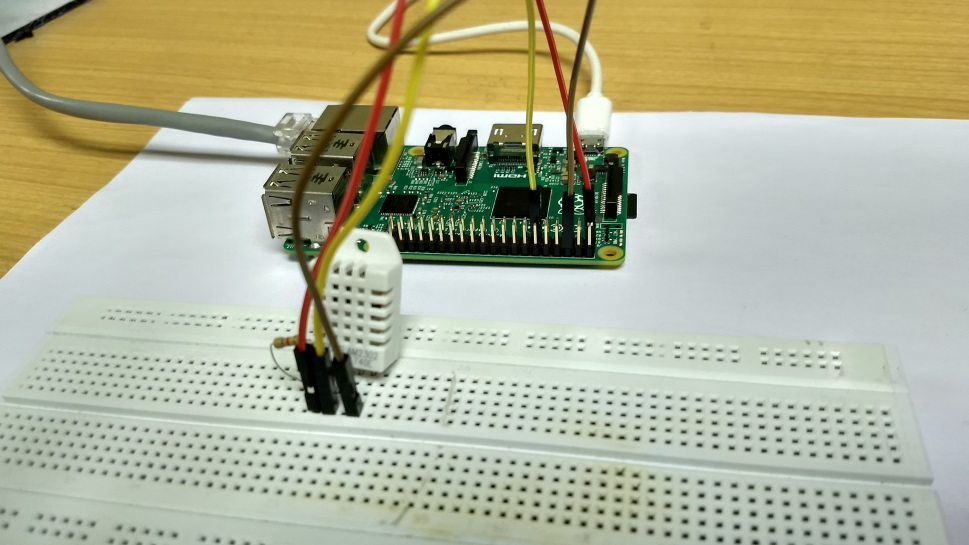

Hardware Requirements:

- Arduino Uno/Nano or ESP32 development board

- Breadboard and jumper wires

- DS18B20 temperature sensor (or DHT22)

- 4.7kOhm pull-up resistor (for DS18B20)

- USB cable for programming

Software Requirements:

- Arduino IDE installed and configured

- Required libraries: OneWire, DallasTemperature

Skills Checklist:

Temperature sensors are among the most common sensors in IoT applications. Here’s what makes them special:

Why Temperature Matters in IoT: - HVAC systems adjust heating/cooling based on readings - Cold chain monitoring ensures vaccine/food safety - Industrial processes require precise temperature control - Weather stations track environmental conditions

Common Temperature Sensor Types: | Sensor | Interface | Accuracy | Best For | |——–|———–|———-|———-| | DS18B20 | 1-Wire digital | +/-0.5C | Multi-sensor chains | | DHT22 | Proprietary digital | +/-0.5C | Temp + humidity combo | | Thermistor | Analog | +/-1C | Low cost, fast response | | Thermocouple | Analog | +/-2C | Extreme temperatures |

Tip: DS18B20 is great for beginners because each sensor has a unique ID, allowing multiple sensors on one wire!

531.3 Temperature Sensors Overview

%%{init: {'theme':'base', 'themeVariables': {'primaryColor':'#2C3E50','primaryTextColor':'#fff','primaryBorderColor':'#16A085','lineColor':'#16A085','secondaryColor':'#E67E22','tertiaryColor':'#ECF0F1','fontSize':'10px'}}}%%

flowchart TB

subgraph before["BEFORE POWER ON"]

B1["Check VCC voltage<br/>3.3V or 5V?"]

B2["Verify GND connection<br/>Common ground?"]

B3["Data pin correct GPIO?<br/>Check pinout diagram"]

B4["Pull-up resistor<br/>4.7k for I2C/1-Wire"]

end

subgraph first["FIRST TEST"]

F1["I2C Scan<br/>Address detected?"]

F2["Raw value reading<br/>Non-zero response?"]

F3["Known reference<br/>Ice water = 0C"]

end

subgraph debug["COMMON FAILURES"]

D1["No response -> Check wiring/address"]

D2["Wrong values -> Check voltage/timing"]

D3["Unstable -> Add filtering/decoupling"]

D4["Drift -> Calibrate/thermal isolation"]

end

before --> first

first --> debug

style before fill:#E8F5E9,stroke:#16A085

style first fill:#E3F2FD,stroke:#2C3E50

style debug fill:#FFF3E0,stroke:#E67E22

531.4 DS18B20 (1-Wire Digital Temperature)

Source: NPTEL Internet of Things Course, IIT Kharagpur - The DHT22 is one of the most common temperature/humidity sensors for IoT projects due to its low cost, ease of use, and adequate accuracy for most applications.

Specifications:

- Temperature Range: -55C to 125C (+/-0.5C accuracy)

- Interface: 1-Wire (multiple sensors on one pin)

- Resolution: 9-12 bit configurable

- Power: 3.0-5.5V, parasitic power mode available

ESP32 Implementation:

#include <OneWire.h>

#include <DallasTemperature.h>

#define ONE_WIRE_BUS 4 // GPIO4

OneWire oneWire(ONE_WIRE_BUS);

DallasTemperature sensors(&oneWire);

// Store number of devices

int numberOfDevices;

DeviceAddress tempDeviceAddress;

void setup() {

Serial.begin(115200);

sensors.begin();

// Get number of devices on the bus

numberOfDevices = sensors.getDeviceCount();

Serial.print("Found ");

Serial.print(numberOfDevices);

Serial.println(" temperature sensors");

// Print addresses

for(int i=0; i<numberOfDevices; i++) {

if(sensors.getAddress(tempDeviceAddress, i)) {

Serial.print("Sensor ");

Serial.print(i);

Serial.print(" Address: ");

printAddress(tempDeviceAddress);

Serial.println();

}

}

}

void loop() {

sensors.requestTemperatures();

for(int i=0; i<numberOfDevices; i++) {

if(sensors.getAddress(tempDeviceAddress, i)) {

float tempC = sensors.getTempC(tempDeviceAddress);

Serial.print("Sensor ");

Serial.print(i);

Serial.print(": ");

Serial.print(tempC);

Serial.println("C");

}

}

delay(1000);

}

void printAddress(DeviceAddress deviceAddress) {

for (uint8_t i = 0; i < 8; i++) {

if (deviceAddress[i] < 16) Serial.print("0");

Serial.print(deviceAddress[i], HEX);

}

}Key Advantages: - Unique 64-bit address: Each sensor has factory-programmed ID - Multi-sensor bus: Connect dozens of sensors on single GPIO pin - Digital output: No ADC needed, noise-immune over long cables - Parasitic power: Can operate with only 2 wires (data + ground)

Common Issues and Fixes: | Problem | Likely Cause | Solution | |———|————–|———-| | No sensors found | Missing pull-up | Add 4.7kOhm between data and VCC | | Reads 85C | Conversion incomplete | Wait 750ms after requestTemperatures() | | Reads -127C | CRC error | Check wiring, reduce cable length | | Intermittent | Long cables | Use lower resolution (9-bit = 93ms) |

531.5 Thermocouple-Based Temperature Sensors

How Thermocouples Work:

Thermocouples generate a small voltage (microvolts) based on the temperature difference between two junctions of dissimilar metals. This is called the Seebeck effect.

Thermocouple Types:

| Type | Metals | Range | Typical Use |

|---|---|---|---|

| K | Chromel/Alumel | -200 to 1250C | General purpose |

| J | Iron/Constantan | -40 to 750C | Industrial |

| T | Copper/Constantan | -200 to 350C | Low temperature |

| E | Chromel/Constantan | -200 to 900C | Highest output |

Cold Junction Compensation:

Thermocouples measure temperature difference, not absolute temperature. You need a reference junction (cold junction) at known temperature. Most thermocouple amplifier ICs (MAX31855, MAX6675) include built-in cold junction compensation.

531.6 Humidity Sensors Comparison

DHT22 (AM2302) Implementation:

The DHT22 combines temperature and humidity sensing in one package, making it popular for environmental monitoring.

Key DHT22 Characteristics:

- Temperature: -40 to 80C (+/-0.5C)

- Humidity: 0-100% RH (+/-2-5%)

- Sampling rate: 0.5 Hz (one reading every 2 seconds)

- Interface: Proprietary single-wire protocol

The DHT22 requires a minimum 2-second interval between readings. Reading faster causes the sensor to return stale data or errors. Always include delay(2000) in your loop when using DHT sensors.

void loop() {

float temp = dht.readTemperature();

float humidity = dht.readHumidity();

if (isnan(temp) || isnan(humidity)) {

Serial.println("Failed to read from DHT!");

}

delay(2000); // CRITICAL: Wait at least 2 seconds

}531.7 Knowledge Check

Question 1: What is the minimum time required between DHT22 sensor readings?

Explanation: The DHT22 sensor requires at least 2 seconds between readings for the internal measurement cycle to complete. Reading faster will result in errors or repeated values because the sensor hasn’t finished converting temperature/humidity measurements.

Question 2: A DS18B20 sensor consistently reads 85.0C immediately after power-on. What does this indicate?

Explanation: 85.0C (0x0550) is the DS18B20’s power-on reset value, indicating “conversion not ready.” The sensor needs up to 750ms (at 12-bit resolution) to complete temperature conversion. Always wait for conversion to complete before reading.

531.8 Summary

This chapter covered temperature sensor implementation fundamentals:

- DS18B20 1-Wire sensors enable multi-sensor networks on a single GPIO pin with unique addressing

- DHT22 sensors provide combined temperature and humidity but require 2-second minimum intervals

- Thermocouples measure extreme temperatures using the Seebeck effect with cold junction compensation

- Proper pull-up resistors (4.7kOhm for 1-Wire, 10kOhm for DHT) ensure reliable communication

- Common error values (85C, -127C, NaN) indicate specific failure modes that guide debugging

531.9 What’s Next?

Now that you understand temperature sensors, continue to learn about motion and environmental sensors including accelerometers, gyroscopes, and barometric pressure sensors.

531.10 See Also

- Sensor Fundamentals - Comprehensive sensor characteristics

- Sensor Calibration Lab - Hands-on calibration techniques

- Best Practices & Labs - Implementation guidelines