%%{init: {'theme': 'base', 'themeVariables': { 'primaryColor': '#2C3E50', 'primaryTextColor': '#fff', 'primaryBorderColor': '#16A085', 'lineColor': '#16A085', 'secondaryColor': '#E67E22'}}}%%

graph TB

M["Master"]

S1["Slave 1"]

S2["Slave 2"]

M -->|"MOSI (Master Out)"| S1

S1 -->|"MISO (Slave Out)"| M

M -->|"SCK (Clock)"| S1

M -->|"SS1 (Chip Select)"| S1

M -->|"MOSI (Shared)"| S2

S2 -->|"MISO (Shared)"| M

M -->|"SCK (Shared)"| S2

M -->|"SS2 (Dedicated)"| S2

style M fill:#2C3E50,stroke:#16A085,color:#fff

style S1 fill:#16A085,stroke:#16A085,color:#fff

style S2 fill:#16A085,stroke:#16A085,color:#fff

795 SPI: Serial Peripheral Interface Protocol

795.1 Learning Objectives

By the end of this section, you will be able to:

- Understand SPI Architecture: Explain the four-wire structure with MOSI, MISO, SCK, and SS

- Configure SPI Modes: Select appropriate clock polarity (CPOL) and phase (CPHA)

- Wire SPI Devices: Connect multiple slaves using chip select lines

- Compare Protocols: Choose between SPI, I2C, and UART for specific applications

- Debug SPI Issues: Troubleshoot mode mismatch, chip select problems, and signal integrity

- Write SPI Code: Program Arduino/ESP32 to communicate with SD cards and displays

795.2 Prerequisites

Before diving into this chapter, you should be familiar with:

- Wired Communication Fundamentals: Understanding of synchronous communication, full-duplex, multi-point topology

- I2C Protocol: Comparison with I2C helps understand when to choose SPI

795.3 SPI Overview

SPI (Serial Peripheral Interface) is a high-speed, full-duplex synchronous protocol developed by Motorola.

No official standard - implementations vary slightly between manufacturers.

795.3.1 Characteristics

| Feature | Value |

|---|---|

| Wires | 4+ wires (SCLK, MOSI, MISO, + 1 SS per slave) |

| Topology | Multi-point (star) |

| Sync/Async | Synchronous (SCLK = clock) |

| Duplex | Full-duplex (simultaneous send/receive) |

| Speed | Up to 10+ Mbps (much faster than I2C) |

| Distance | <1 meter (short cables, same PCB) |

| Devices | Unlimited (limited by SS pins available) |

| Master/Slave | Single master, multiple slaves |

795.4 SPI Signals

Signal names (vary by manufacturer):

| Function | Alternative Names |

|---|---|

| SCLK | SCK, CLK (Serial Clock) |

| MOSI | SDI, DI, SI (Master Out Slave In) |

| MISO | SDO, DO, SO (Master In Slave Out) |

| SS | CS, CE (Slave Select / Chip Select) |

SCLK (Serial Clock):

- Clock signal from master

- Slaves synchronize to this clock

MOSI (Master Out, Slave In):

- Data from master to slave

- Master writes, slaves read

MISO (Master In, Slave Out):

- Data from slaves to master

- Slaves write, master reads

SS (Slave Select):

- Active LOW (usually)

- Master pulls LOW to select specific slave

- Separate SS line for each slave

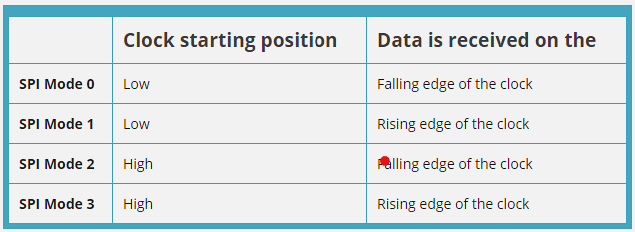

795.5 SPI Modes

SPI has 4 modes based on clock polarity (CPOL) and phase (CPHA):

| Mode | CPOL | CPHA | Clock Idle | Data Sampled |

|---|---|---|---|---|

| 0 | 0 | 0 | LOW | Rising edge |

| 1 | 0 | 1 | LOW | Falling edge |

| 2 | 1 | 0 | HIGH | Falling edge |

| 3 | 1 | 1 | HIGH | Rising edge |

CPOL (Clock Polarity):

- 0 = Clock idle state is LOW

- 1 = Clock idle state is HIGH

CPHA (Clock Phase):

- 0 = Data sampled on leading edge (first transition)

- 1 = Data sampled on trailing edge (second transition)

Most common: Mode 0 and Mode 3

Important: Master and slave must use same mode!

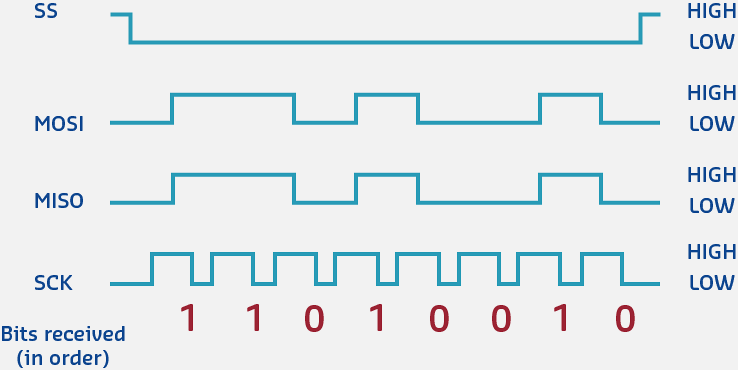

795.6 SPI Data Transfer

Full-duplex simultaneous transfer:

SS ____ ________

\______________________/

SCLK ___ _ _ _ _ _ ___

\_/ \_/ \_/ \_/ \_/ \_/

MOSI ====X===X===X===X===X===X=====

(Master sends data to slave)

MISO ====X===X===X===X===X===X=====

(Slave sends data to master)

Bit: 7 6 5 4 3 2 1 0Process:

- Master pulls SS LOW (select slave)

- Master generates clock pulses on SCLK

- On each clock pulse:

- Master outputs bit on MOSI

- Slave outputs bit on MISO

- Both sides shift data simultaneously

- After 8 (or 16) bits, transaction complete

- Master pulls SS HIGH (deselect slave)

Data transmitted MSB first (most significant bit first) - can be configured.

795.7 Arduino/ESP32 SPI Example

#include <SPI.h>

// SS (Chip Select) pin

#define SS_PIN 5

void setup() {

Serial.begin(115200);

// Initialize SPI

SPI.begin();

// Configure SS pin

pinMode(SS_PIN, OUTPUT);

digitalWrite(SS_PIN, HIGH); // Deselect

Serial.println("SPI Initialized");

}

void loop() {

// Select slave

digitalWrite(SS_PIN, LOW);

// Transfer data (sends 0xAA, receives slave's response)

SPI.beginTransaction(SPISettings(1000000, MSBFIRST, SPI_MODE0));

byte response = SPI.transfer(0xAA);

SPI.endTransaction();

// Deselect slave

digitalWrite(SS_PIN, HIGH);

Serial.print("Sent: 0xAA, Received: 0x");

Serial.println(response, HEX);

delay(1000);

}Wiring (ESP32 default SPI pins):

ESP32 GPIO 18 (SCLK) -> Slave SCLK

ESP32 GPIO 23 (MOSI) -> Slave MOSI

ESP32 GPIO 19 (MISO) -> Slave MISO

ESP32 GPIO 5 (SS) -> Slave SS/CS

ESP32 GND -> Slave GNDCommon SPI devices:

- SD card modules

- TFT/OLED displays

- NRF24L01 radio modules

- ADXL345 accelerometer

- MCP3008 ADC

Choosing the Right SPI Mode:

- Check device datasheet - Look for CPOL/CPHA or explicit mode number

- Try Mode 0 first - Works with ~80% of SPI devices

- Try Mode 3 second - If Mode 0 fails (some displays, Ethernet)

- Modes 1 and 2 rare - Only specific industrial/legacy devices

Common Mode Assignments:

- SD Cards: Mode 0 (CPOL=0, CPHA=0)

- TFT Displays: Mode 0 or Mode 3

- ADXL345: Mode 3 (CPOL=1, CPHA=1)

- NRF24L01: Mode 0

- W5500 Ethernet: Mode 0

Debugging Mode Issues:

- Symptom: Garbled data, bits shifted

- Solution: Try different modes (SPI_MODE0 through SPI_MODE3)

- Test: Send known byte (0xAA = 10101010), verify response

795.8 Hands-On Lab: SD Card Reader

Objective: Read/write files to SD card via SPI.

#include <SPI.h>

#include <SD.h>

#define SD_CS 5 // Chip Select pin

void setup() {

Serial.begin(115200);

if (!SD.begin(SD_CS)) {

Serial.println("SD card initialization failed!");

return;

}

Serial.println("SD card initialized");

// Write to file

File file = SD.open("/test.txt", FILE_WRITE);

if (file) {

file.println("Hello from ESP32!");

file.close();

Serial.println("File written");

}

// Read from file

file = SD.open("/test.txt");

if (file) {

Serial.println("\nFile contents:");

while (file.available()) {

Serial.write(file.read());

}

file.close();

}

}

void loop() {}795.9 Knowledge Check: SPI Signal Integrity

Scenario: Your data logger uses an SPI flash memory (Winbond W25Q128) rated for 133 MHz clock. Tests at 80 MHz work reliably (98% success rate), but at 133 MHz you see 40% corruption. A logic analyzer reveals clock signal overshoot (+5.8V on 3.3V logic) and ringing (+/-0.8V oscillations lasting 12 ns).

Think about:

- Why do PCB traces behave differently at 133 MHz vs 10 MHz?

- What physical phenomena cause the overshoot and ringing?

Key Insight: At high frequencies, transmission line effects dominate PCB design. A 10 cm trace at 133 MHz becomes an antenna:

- Signal wavelength: lambda = c/f = (3x10^8 m/s) / (133x10^6 Hz) = 2.26 meters

- Critical length: lambda/10 = 22.6 cm (your trace is 10 cm -> significant effects)

- Fast edge time: ~2 ns (10%-90% rise) creates harmonics up to 500 MHz

Root causes:

- Impedance mismatch: 50 ohm PCB trace -> 10 ohm chip pin creates reflection coefficient Gamma = (10-50)/(10+50) = -0.67 (67% negative reflection)

- Reflected wave: Bounces back toward source, interfering with forward signal (ringing)

- Overshoot: Reflected wave adds to forward wave (constructive interference)

Solutions:

- Series termination: 22-33 ohm resistor at source dampens reflections

- Shorter traces: Reduce to <5 cm (<lambda/40 at 133 MHz)

- Controlled impedance: Design 50 ohm traces (width/height ratio)

- Ground plane: Continuous plane under signal reduces loop inductance

Verify Your Understanding:

- Why does this matter more at 133 MHz than 10 MHz? Because lambda/10 at 10 MHz = 3 meters (trace is insignificant). At 133 MHz, lambda/10 = 22 cm (trace is significant fraction).

- Calculate required series resistor: Source impedance (5 ohm) + resistor (27 ohm) = 32 ohm approximately equal to 50 ohm trace impedance (minimizes reflections).

795.10 Protocol Comparison for IoT

795.10.1 When to Use Each Protocol

| Protocol | Best For | Avoid When |

|---|---|---|

| RS-232 | GPS modules, serial debugging, industrial legacy systems | Multiple devices on same bus, high speed needed |

| I2C | Multiple low-speed sensors (temp, humidity, pressure), displays, EEPROMs | High-speed data transfer (video, audio), long cables |

| SPI | High-speed sensors, SD cards, displays, radio modules | Pin count is limited, long-distance communication |

795.10.2 Detailed Comparison

%%{init: {'theme': 'base', 'themeVariables': { 'primaryColor': '#2C3E50', 'primaryTextColor': '#fff', 'primaryBorderColor': '#16A085', 'lineColor': '#16A085', 'secondaryColor': '#E67E22'}}}%%

graph TD

Start["Choose Protocol"]

Start --> Q1{"How many<br/>devices?"}

Q1 -->|"2 only"| UART["UART/RS-232<br/>2 wires<br/>115 kbps<br/>Point-to-point"]

Q1 -->|"3+"| Q2{"Speed<br/>requirement?"}

Q2 -->|"< 400 kbps"| I2C["I2C<br/>2 wires<br/>400 kbps<br/>Up to 112 devices<br/>Addressable"]

Q2 -->|"> 1 Mbps"| SPI["SPI<br/>4+ wires<br/>10+ Mbps<br/>Full-duplex<br/>Fast"]

style Start fill:#2C3E50,stroke:#16A085,color:#fff

style Q1 fill:#7F8C8D,stroke:#16A085,color:#fff

style Q2 fill:#7F8C8D,stroke:#16A085,color:#fff

style UART fill:#E67E22,stroke:#16A085,color:#fff

style I2C fill:#16A085,stroke:#16A085,color:#fff

style SPI fill:#2C3E50,stroke:#16A085,color:#fff

795.10.3 Practical Trade-offs

I2C Advantages:

- Only 2 wires (minimal pins)

- Easy to add devices (just connect to bus)

- Addressable (up to 112 devices)

- Bidirectional on same wire

I2C Disadvantages:

- Slower than SPI

- Pull-up resistors required

- Address conflicts possible

- Limited cable length

SPI Advantages:

- Very fast (10+ Mbps)

- Full-duplex (simultaneous send/receive)

- Simple, no addressing

- No pull-up resistors needed

SPI Disadvantages:

- More wires (4+ pins)

- Separate SS for each slave (pin intensive)

- No multi-master capability

- No flow control

Choose UART when:

- Point-to-point communication (2 devices)

- Serial debugging or console needed

- GPS module, Bluetooth HC-05/HC-06

- Cable lengths up to 15 meters

Choose I2C when:

- Multiple devices (2-112 on same bus)

- Limited pins (only 2 wires available: SDA, SCL)

- Low-to-medium speed OK (< 400 kHz)

- Sensors, displays, EEPROMs, RTCs

Choose SPI when:

- High speed required (1-10+ Mbps)

- Enough pins available (4+ wires)

- SD cards, TFT displays, fast sensors

- Full-duplex needed (simultaneous TX/RX)

Real-World Examples:

- Weather station: I2C (BME280, OLED display on same bus)

- Data logger: SPI (SD card for fast writes)

- GPS tracker: UART (GPS module + serial debug)

- Robot: Mixed (I2C for sensors, SPI for displays, UART for debug)

795.11 Quiz: SPI and Protocol Comparison

795.12 Summary

This chapter covered SPI (Serial Peripheral Interface) protocol and protocol comparison:

- Four-wire interface (SCLK, MOSI, MISO, SS) enables high-speed full-duplex communication

- SPI modes (0-3) define clock polarity and phase - must match between master and slave

- Chip select (SS/CS) lines enable multi-slave configurations with separate select per device

- Speed advantage: 10+ Mbps vs I2C’s 400 kbps, ideal for SD cards, displays, and fast sensors

- Trade-off: More pins (4+ wires) vs I2C’s 2 wires, no multi-master, no addressing

- Protocol selection: UART for point-to-point, I2C for multi-device low-speed, SPI for high-speed

795.13 What’s Next

Having mastered wired protocols, explore complementary topics:

- Wireless Communication: Wi-Fi, Bluetooth, Zigbee, and LoRaWAN for cable-free IoT connectivity

- Industrial Networking: Deep dive into Modbus RTU/TCP, CANopen, EtherCAT, and PROFINET

- Network Protocols: TCP/IP, MQTT, CoAP, and HTTP for application-layer communication

- Sensor Interfacing: Practical projects connecting temperature, humidity, accelerometer, and display modules

- Protocol Analyzers: Using logic analyzers and bus sniffers to debug communication issues

- Wired Communication Overview: Return to the overview page