231 Processes and Systems: PID Control

231.1 Overview

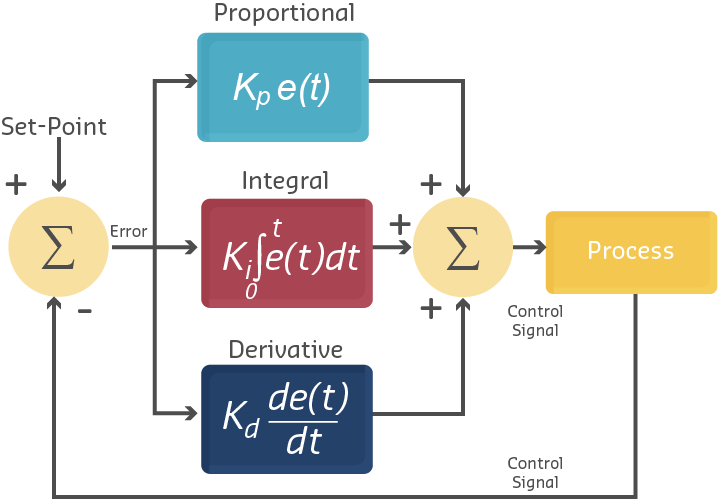

This section covers PID (Proportional-Integral-Derivative) control, the most widely used feedback control algorithm in industrial and IoT applications. PID controllers enable precise, automated control of processes ranging from temperature regulation to motor speed control.

231.2 What You’ll Learn

The PID control content is organized into three focused chapters:

231.2.1 Part 1: PID Control Fundamentals

Learn the foundation of PID control:

- PID Components: Understanding the three terms (P, I, D) and their roles

- Error Calculation: How setpoint, process variable, and error relate

- Proportional Control: How P-term responds to current error magnitude

- P-Only Limitations: Why proportional control alone causes steady-state error

- PID Equation: The mathematical foundation for controller output

231.2.2 Part 2: Integral and Derivative Control

Master the I and D terms:

- Integral Control: Eliminating steady-state error through error accumulation

- Integral Windup: Preventing dangerous over-accumulation

- Derivative Control: Using rate of change to reduce overshoot

- PID Configuration Selection: When to use P, PI, PID, or PD

- Tuning Philosophy: Why conservative gains outperform aggressive tuning

231.2.3 Part 3: PID Implementation and Labs

Hands-on implementation:

- Arduino/ESP32 Code: Complete PID controller class in C++

- Lab Exercises: Systematic tuning exploration with P, PI, and PID

- Python Framework: Production-ready simulation and auto-tuning

- Performance Metrics: Measuring settling time, overshoot, and error

- Distributed Control: Edge vs cloud control architecture decisions

231.3 Prerequisites

Before starting this section, you should understand:

- Basic feedback control concepts (open-loop vs closed-loop)

- Process variables, setpoints, and error signals

- Simple programming concepts (variables, loops, functions)

231.4 Learning Path

| Chapter | Focus | Difficulty | Time |

|---|---|---|---|

| PID Fundamentals | Theory & P-term | Intermediate | 25 min |

| Integral & Derivative | I & D terms | Intermediate | 30 min |

| Implementation | Code & Labs | Advanced | 45 min |

231.5 Quick Reference

PID Equation: \[ u(t) = K_p \cdot e(t) + K_i \cdot \int_{0}^{t} e(\tau) \, d\tau + K_d \cdot \frac{de(t)}{dt} \]

Common Configurations:

| Mode | When to Use |

|---|---|

| P | Simple systems, some error acceptable |

| PI | Most common, general-purpose control |

| PID | High-performance, minimal overshoot needed |

| PD | Fast servos without steady-state concerns |

231.6 Start Learning

Recommended: Begin with PID Control Fundamentals for a solid foundation.

Advanced: Jump directly to Implementation and Labs if you already understand PID theory.