%%{init: {'theme': 'base', 'themeVariables': { 'primaryColor': '#2C3E50', 'primaryTextColor': '#fff', 'primaryBorderColor': '#16A085', 'lineColor': '#16A085', 'secondaryColor': '#E67E22', 'tertiaryColor': '#ecf0f1', 'fontSize': '15px'}}}%%

flowchart LR

SP["Target:<br/>22 deg C"] --> Comp["Compare"]

Sensor["Temperature<br/>Sensor:<br/>21 deg C"] --> Comp

Comp -->|Error: +1 deg C<br/>Need Heat| MCU["Smart<br/>Thermostat<br/>Controller"]

MCU -->|Activate| Heater["Heating<br/>System"]

Heater -->|Warm Air| Room["Room<br/>Environment"]

Room -.->|Measure<br/>Temperature| Sensor

style SP fill:#16A085,stroke:#2C3E50,stroke-width:2px,color:#fff

style Comp fill:#E67E22,stroke:#16A085,stroke-width:2px,color:#fff

style MCU fill:#2C3E50,stroke:#16A085,stroke-width:2px,color:#fff

style Heater fill:#E67E22,stroke:#16A085,stroke-width:2px,color:#fff

style Sensor fill:#2C3E50,stroke:#16A085,stroke-width:2px,color:#fff

style Room fill:#7F8C8D,stroke:#16A085,stroke-width:2px,color:#fff

222 PID: Open-Loop and Closed-Loop Systems

222.1 Learning Objectives

By the end of this chapter, you will be able to:

- Distinguish Control Types: Compare open-loop and closed-loop control strategies and their applications

- Identify System Characteristics: Recognize advantages and disadvantages of each control approach

- Apply Decision Frameworks: Use systematic criteria to select appropriate control architecture

- Design IoT Control Systems: Choose between local edge control and cloud-based control loops

Core concept: Open-loop systems execute predetermined actions blindly (like a timer), while closed-loop systems continuously monitor output and adjust (like a thermostat). Why it matters: Closed-loop systems can self-correct errors and adapt to disturbances, but require sensors and more complexity. Key takeaway: Most IoT control applications benefit from closed-loop feedback, but simple monitoring-only devices may operate open-loop at the device level while the overall system implements feedback through cloud coordination.

222.2 Prerequisites

Before diving into this chapter, you should be familiar with:

- Feedback Fundamentals: Understanding feedback concepts, negative vs positive feedback, and IoT applications

- Sensor Fundamentals: Sensor characteristics for feedback measurement

- Actuators: Control outputs for implementing corrections

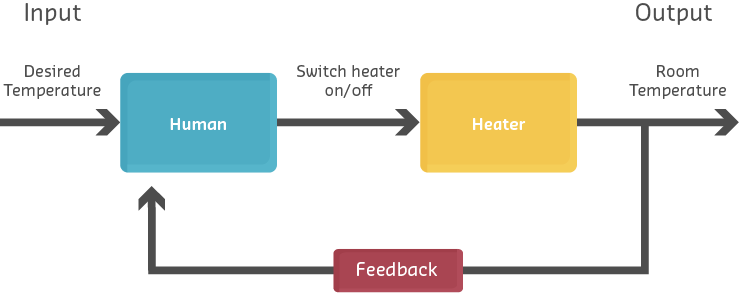

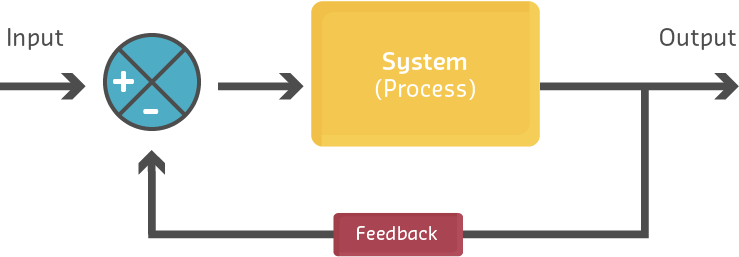

222.3 Closed-Loop Feedback Systems

In a closed-loop system, a portion of the output is fed back to the input and either added to (positive feedback) or subtracted from (negative feedback) the input signal. This creates a self-regulating system that continuously updates based on current output conditions.

Closed-Loop Feedback System Block Diagram: Set point is compared with measured output, generating error signal. Controller processes error and adjusts system input. Feedback sensor creates continuous regulation loop.

Key Components:

- Set Point (SP): The desired target value

- Error Signal: Difference between set point and measured output

- Controller: Processes error and determines corrective action

- Process/Plant: The system being controlled

- Feedback Sensor: Measures actual output

- Comparator: Computes error = SP - measured value

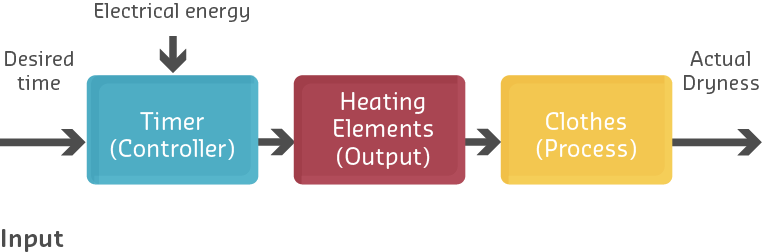

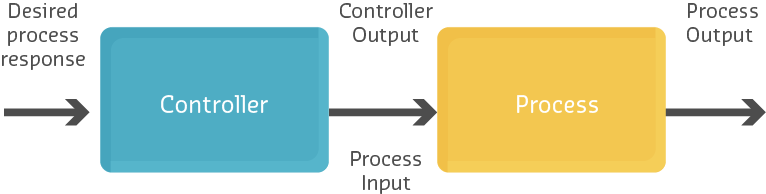

222.4 Open-Loop Control Systems

An open-loop system does not monitor or measure its output. It executes a predetermined action based solely on the input, without feedback. This is also called a non-feedback system.

%%{init: {'theme': 'base', 'themeVariables': { 'primaryColor': '#2C3E50', 'primaryTextColor': '#fff', 'primaryBorderColor': '#16A085', 'lineColor': '#16A085', 'secondaryColor': '#E67E22', 'tertiaryColor': '#ecf0f1', 'fontSize': '16px'}}}%%

graph LR

Input["Input<br/>(Set Timer<br/>60 min)"] --> Controller["Controller<br/>(Timer)"]

Controller -->|Run for<br/>60 minutes| Process["Process<br/>(Dryer)"]

Process -->|Unknown State| Output["Output<br/>(Clothes)"]

style Input fill:#16A085,stroke:#2C3E50,stroke-width:2px,color:#fff

style Controller fill:#2C3E50,stroke:#16A085,stroke-width:2px,color:#fff

style Process fill:#E67E22,stroke:#16A085,stroke-width:2px,color:#fff

style Output fill:#7F8C8D,stroke:#16A085,stroke-width:2px,color:#fff

Open-Loop System Block Diagram: Input (timer setting) determines controller action without measuring output state. System executes predetermined sequence with no knowledge of actual results.

Characteristics:

- No feedback path from output to input

- Cannot self-correct for disturbances or errors

- Simpler and less expensive to implement

- Suitable when output is predictable and disturbances are minimal

222.5 Open-Loop in IoT Sensing Applications

Open-loop architectures are increasingly common in IoT data collection scenarios where:

- Device only senses and transmits data

- No local actuation required

- Analysis and decision-making occur remotely

- Feedback loop exists at system level, but not device level

%%{init: {'theme': 'base', 'themeVariables': { 'primaryColor': '#2C3E50', 'primaryTextColor': '#fff', 'primaryBorderColor': '#16A085', 'lineColor': '#16A085', 'secondaryColor': '#E67E22', 'tertiaryColor': '#ecf0f1', 'fontSize': '15px'}}}%%

flowchart TB

Sensor["Sensor Node<br/>(Open-Loop)"] -->|Periodic Data<br/>Transmission| Cloud["Cloud<br/>Platform"]

Sensor -->|Temp: 24 deg C<br/>Humidity: 65%| Cloud

Cloud -->|Store & Analyze| DB["Data<br/>Storage"]

Cloud -->|Dashboard| User["Human<br/>Operator"]

style Sensor fill:#2C3E50,stroke:#16A085,stroke-width:2px,color:#fff

style Cloud fill:#16A085,stroke:#2C3E50,stroke-width:2px,color:#fff

style DB fill:#7F8C8D,stroke:#16A085,stroke-width:2px,color:#fff

style User fill:#E67E22,stroke:#16A085,stroke-width:2px,color:#fff

IoT Sensor Node Open-Loop Data Collection: Device only senses and transmits data periodically without local actuation. No device-level feedback loop, but human operators or cloud systems may take action based on reported data.

However, at the system level, there may be feedback:

%%{init: {'theme': 'base', 'themeVariables': { 'primaryColor': '#2C3E50', 'primaryTextColor': '#fff', 'primaryBorderColor': '#16A085', 'lineColor': '#16A085', 'secondaryColor': '#E67E22', 'tertiaryColor': '#ecf0f1', 'fontSize': '14px'}}}%%

graph TB

subgraph Edge ["Edge Devices (Open-Loop Individually)"]

S["Sensor Node:<br/>Measure Soil<br/>Moisture 25%"]

A["Actuator Node:<br/>Irrigation Valve"]

end

subgraph Cloud ["Cloud System (Closed-Loop Coordination)"]

P["IoT Platform"]

R["Rule: IF moisture<br/>< 30% THEN<br/>Activate Irrigation"]

D["Database &<br/>Analytics"]

end

S -->|Transmit:<br/>Moisture = 25%| P

P --> R

R -->|Evaluate| D

R -->|Command:<br/>Open Valve| A

A -->|Water Soil| Field["Field"]

Field -.->|Moisture Increases<br/>to 60%| S

style S fill:#2C3E50,stroke:#16A085,stroke-width:2px,color:#fff

style A fill:#E67E22,stroke:#16A085,stroke-width:2px,color:#fff

style P fill:#16A085,stroke:#2C3E50,stroke-width:2px,color:#fff

style R fill:#E67E22,stroke:#16A085,stroke-width:2px,color:#fff

style Field fill:#7F8C8D,stroke:#16A085,stroke-width:2px,color:#fff

System-Level Closed-Loop with Device-Level Open-Loop: Individual sensor and actuator nodes operate open-loop (no local feedback), but cloud platform creates system-level feedback by coordinating remote sensing and actuation based on rules.

This architecture demonstrates that while individual devices operate open-loop, the overall IoT system implements closed-loop control through cloud-based coordination.

222.6 Comparing Open and Closed Loop Systems

Understanding the trade-offs between open-loop and closed-loop systems is crucial for IoT system design.

222.6.1 Advantages and Disadvantages

222.6.2 Decision Matrix

%%{init: {'theme': 'base', 'themeVariables': { 'primaryColor': '#2C3E50', 'primaryTextColor': '#fff', 'primaryBorderColor': '#16A085', 'lineColor': '#16A085', 'secondaryColor': '#E67E22', 'tertiaryColor': '#ecf0f1', 'fontSize': '15px'}}}%%

graph TD

Start{{"Control System<br/>Design Decision"}} --> Q1{"Precision<br/>Control<br/>Required?"}

Q1 -->|Yes| Q2{"Environment<br/>Predictable?"}

Q1 -->|No| Q3{"Cost<br/>Constraint?"}

Q2 -->|No| CL["Use<br/>Closed-Loop<br/>(Feedback)"]

Q2 -->|Yes| Q4{"Disturbances<br/>Present?"}

Q3 -->|High| OL["Use<br/>Open-Loop<br/>(No Feedback)"]

Q3 -->|Low| Q2

Q4 -->|Yes| CL

Q4 -->|No| Q5{"Safety<br/>Critical?"}

Q5 -->|Yes| CL

Q5 -->|No| OL

style Start fill:#16A085,stroke:#2C3E50,stroke-width:3px,color:#fff

style CL fill:#2C3E50,stroke:#16A085,stroke-width:3px,color:#fff

style OL fill:#E67E22,stroke:#16A085,stroke-width:3px,color:#fff

Open-Loop vs Closed-Loop Decision Tree: Precision requirements, environmental predictability, disturbances, cost constraints, and safety considerations determine appropriate control architecture.

This variant presents a decision framework for architects choosing between control approaches based on system requirements.

%%{init: {'theme': 'base', 'themeVariables': { 'primaryColor': '#2C3E50', 'primaryTextColor': '#fff', 'primaryBorderColor': '#16A085', 'lineColor': '#16A085', 'secondaryColor': '#E67E22', 'tertiaryColor': '#7F8C8D', 'fontSize': '11px'}}}%%

graph TB

subgraph Decision["CONTROL ARCHITECTURE SELECTION"]

direction TB

Q1{{"Response Time<br/>Requirement?"}}

Q2{{"Network<br/>Available?"}}

Q3{{"Safety<br/>Critical?"}}

Q4{{"Power<br/>Constrained?"}}

end

subgraph OpenLoop["OPEN-LOOP<br/>(No Feedback)"]

OL1["✓ Lowest cost<br/>✓ Lowest power<br/>✓ Simplest design"]

OL2["✗ No self-correction<br/>✗ Drift over time<br/>✗ Cannot adapt"]

OL3["USE FOR:<br/>• Data collection only<br/>• Simple timers<br/>• Low-precision needs"]

end

subgraph EdgeClosed["EDGE CLOSED-LOOP<br/>(Local Feedback)"]

EC1["✓ Fast response (ms)<br/>✓ Works offline<br/>✓ Autonomous safety"]

EC2["✗ Higher device cost<br/>✗ Local processing load<br/>✗ Limited analytics"]

EC3["USE FOR:<br/>• Motor control<br/>• Safety systems<br/>• Real-time PID"]

end

subgraph CloudClosed["CLOUD CLOSED-LOOP<br/>(Remote Feedback)"]

CC1["✓ Centralized logic<br/>✓ Advanced analytics<br/>✓ Multi-device coordination"]

CC2["✗ Network latency<br/>✗ Requires connectivity<br/>✗ Failure vulnerability"]

CC3["USE FOR:<br/>• Building HVAC<br/>• Fleet management<br/>• Non-critical automation"]

end

Q1 -->|"< 100ms"| EdgeClosed

Q1 -->|"> 1s OK"| Q2

Q2 -->|"Unreliable"| EdgeClosed

Q2 -->|"Reliable"| Q3

Q3 -->|"Yes"| EdgeClosed

Q3 -->|"No"| Q4

Q4 -->|"Very Low"| OpenLoop

Q4 -->|"Adequate"| CloudClosed

style Decision fill:#2C3E50,color:#fff

style OpenLoop fill:#7F8C8D,color:#fff

style EdgeClosed fill:#16A085,color:#fff

style CloudClosed fill:#E67E22,color:#fff

222.7 Practical Example: Water Quality Monitoring

222.8 Design Considerations: Edge vs Cloud Control

Option A: Local Edge Control - PID controller runs on edge device (microcontroller, gateway) with sensor and actuator. Control loop latency 1-10ms, operates independently of network.

Option B: Cloud-Based Control - Sensor data sent to cloud, PID algorithm runs in cloud, commands sent back to actuator. Enables advanced analytics but adds 100-500ms network latency.

Decision Factors:

Choose Local Edge when: Control loop requires <50ms response time (motor speed, safety shutoffs), network connectivity is unreliable or intermittent, bandwidth costs are significant (cellular IoT), or system must operate autonomously during outages.

Choose Cloud-Based when: Control decisions benefit from cross-device coordination (building HVAC optimizing across 100 zones), advanced ML models improve control quality, historical data analysis drives setpoint adjustments, or remote monitoring and tuning are required.

Latency comparison: Local edge achieves 1-10ms control loop. Cloud-based adds 50-200ms (Wi-Fi to internet) or 100-500ms (cellular) round-trip, making it unsuitable for systems with >10Hz disturbance frequencies.

Hybrid approach: Run fast local PID for stability, use cloud for setpoint optimization and supervisory control.

222.9 Knowledge Check

222.10 Summary

This chapter compared open-loop and closed-loop control systems:

- Closed-Loop Systems: Continuously monitor output and self-correct errors using feedback sensors

- Open-Loop Systems: Execute predetermined actions without measuring results

- Decision Factors: Precision requirements, environmental predictability, disturbances, cost, and safety

- IoT Architecture: Device-level open-loop with system-level closed-loop is common in distributed IoT

- Edge vs Cloud: Local edge control for fast response, cloud control for analytics and coordination

222.11 What’s Next

The next chapter explores PID Control Theory, covering the mathematics and behavior of Proportional, Integral, and Derivative control terms.

- Feedback Fundamentals - Foundation concepts

- PID Control Theory - P, I, D term mathematics

- PID Tuning and Applications - Real-world implementation

- Edge Computing - Local vs cloud control