%%{init: {'theme': 'base', 'themeVariables': {'primaryColor': '#2C3E50', 'primaryTextColor': '#fff', 'primaryBorderColor': '#16A085', 'lineColor': '#E67E22', 'secondaryColor': '#16A085', 'tertiaryColor': '#7F8C8D'}}}%%

graph TB

A[HART Evolution] --> B[Wired HART<br/>1980s-Present]

A --> C[WirelessHART<br/>2007+]

B --> B1[4-20 mA Current Loop<br/>Analog + Digital]

B --> B2[Point-to-Point Wiring<br/>Expensive Installation]

B --> B3[Mature Ecosystem<br/>40+ Million Devices]

C --> C1[2.4 GHz IEEE 802.15.4<br/>Mesh Networking]

C --> C2[TDMA + Channel Hopping<br/>Deterministic & Reliable]

C --> C3[Wireless Extension<br/>Same Data Model]

B1 --> D1[Legacy Infrastructure<br/>Proven Technology]

C1 --> D2[Retrofit Applications<br/>80% Cost Savings]

style A fill:#E67E22,stroke:#2C3E50,color:#fff

style B fill:#2C3E50,stroke:#16A085,color:#fff

style C fill:#16A085,stroke:#2C3E50,color:#fff

1001 WirelessHART Fundamentals and Architecture

1001.1 Learning Objectives

By the end of this chapter, you will be able to:

- Understand WirelessHART’s position in industrial automation

- Explain the evolution from wired HART to WirelessHART

- Describe the WirelessHART protocol stack and network architecture

- Identify key components: Gateway, Network Manager, field devices

- Understand why WirelessHART is designed for industrial process control

1001.2 Introduction

WirelessHART is a wireless mesh networking protocol specifically designed for industrial process automation and control. It’s the wireless extension of the Highway Addressable Remote Transducer (HART) Protocol, which has been the dominant standard for industrial field devices since the 1980s. WirelessHART enables wireless communication for sensors, actuators, and control devices in harsh industrial environments while maintaining the reliability and determinism required for process control.

In one sentence: WirelessHART provides deterministic, industrial-grade wireless communication using TDMA scheduling and channel hopping to achieve 99.999% reliability for process automation.

Remember this: Use WirelessHART for industrial control loops requiring guaranteed latency (<100ms) and existing HART device compatibility; use Zigbee or Thread for consumer/building automation where best-effort delivery is acceptable.

Imagine a huge oil refinery with thousands of sensors measuring temperature, pressure, and flow rates across miles of pipes and equipment. Traditionally, each sensor needed a physical wire running back to the control room—expensive to install, maintain, and modify. WirelessHART makes these sensors wireless while maintaining the extreme reliability industrial settings require.

But here’s the challenge: Industrial environments are brutal for wireless signals. Metal pipes and tanks block signals. Electrical motors create interference. A sensor reading can’t just “drop out” when someone’s life depends on detecting dangerous pressure levels. Home Wi-Fi can tolerate occasional dropped packets—industrial control systems cannot.

WirelessHART solves this with several clever techniques: mesh networking (if one path fails, data routes around it through other sensors), time-synchronized communication (devices take turns transmitting so they never interfere), and channel hopping (rapidly switching frequencies to avoid interference). It’s like having multiple backup routes for your data, scheduled so carefully that collisions never happen.

Think of it as the difference between a casual group chat (where messages sometimes get lost) and air traffic control communication (where every message must get through reliably). WirelessHART is designed for mission-critical industrial applications where reliability isn’t just important—it’s mandatory.

| Term | Simple Explanation |

|---|---|

| HART | Highway Addressable Remote Transducer—1980s industrial standard |

| WirelessHART | Wireless version of HART for industrial automation sensors |

| Mesh Network | Devices relay messages for each other—multiple paths to destination |

| TDMA | Time Division Multiple Access—devices take scheduled turns transmitting |

| Channel Hopping | Rapidly switching radio frequencies to avoid interference |

| Deterministic | Communication with predictable, guaranteed timing (not random) |

| Time Slot | Assigned time window when a specific device can transmit |

| Blacklisting | Marking bad frequencies to avoid using them |

1001.3 HART Protocol Background

1001.3.1 Highway Addressable Remote Transducer (HART)

HART was developed in the 1980s as a hybrid analog/digital communication protocol for industrial field devices (sensors, actuators, controllers).

Original HART (Wired): - Superimposes digital signals on 4-20 mA analog current loops - Backward compatible with existing analog infrastructure - Allows digital communication while maintaining analog control - Became industry standard for process automation

{fig-alt=“HART protocol evolution showing wired HART (1980s) with 4-20mA current loop analog/digital hybrid communication versus WirelessHART (2007) using 2.4 GHz mesh networking with TDMA and channel hopping for industrial automation”}

Why wireless extension? - Many industrial locations difficult to wire (tanks, rotating equipment, hazardous areas) - Retrofit existing plants without extensive cabling - Reduce installation costs (wiring can be 80% of deployment cost) - Enable temporary monitoring during commissioning/maintenance - Monitor mobile equipment

1001.3.2 WirelessHART Development

Timeline: - 2004: HART Communication Foundation starts wireless initiative - 2007: WirelessHART specification released (HART 7.0) - 2008: IEC 62591 international standard - 2010+: Widespread industrial deployments

Design goals: - Industrial-grade reliability (99.999%+ availability) - Deterministic communication (predictable latency) - Coexistence with other 2.4 GHz systems - Self-organizing, self-healing mesh - Backward compatible with HART ecosystem - Secure communication

1001.4 WirelessHART Architecture

The WirelessHART architecture centers on the Gateway, which bridges the wireless mesh to the plant control system (DCS/SCADA). The Network Manager handles all scheduling, routing graph computation, and network diagnostics. Field devices form a self-healing mesh using time-synchronized communication with channel hopping for reliability.

This variant compares WirelessHART and Zigbee for industrial applications:

%%{init: {'theme': 'base', 'themeVariables': {'primaryColor': '#2C3E50', 'primaryTextColor': '#fff', 'primaryBorderColor': '#16A085', 'lineColor': '#E67E22', 'secondaryColor': '#16A085', 'tertiaryColor': '#7F8C8D', 'fontSize': '11px'}}}%%

graph TB

subgraph WHART["WirelessHART"]

W1["TDMA: Deterministic<br/>Guaranteed latency"]

W2["Channel hopping<br/>15 frequencies"]

W3["99.999% reliability<br/>Industrial-grade"]

W4["Centralized Network Manager<br/>Optimal scheduling"]

W5["HART commands<br/>30M legacy devices"]

end

subgraph ZIGBEE["Zigbee (Industrial)"]

Z1["CSMA/CA: Best-effort<br/>Variable latency"]

Z2["Single channel<br/>Interference vulnerable"]

Z3["~99% reliability<br/>Consumer-grade"]

Z4["Distributed routing<br/>Self-organizing"]

Z5["ZCL clusters<br/>Smart home focus"]

end

CHOICE["Industrial IoT Choice:<br/>━━━━━━━━━━━━<br/>WirelessHART: Safety-critical<br/>process control (100ms loops)<br/>━━━━━━━━━━━━<br/>Zigbee: Monitoring-only<br/>non-critical sensors"]

WHART --> CHOICE

ZIGBEE --> CHOICE

style WHART fill:#16A085,stroke:#2C3E50,color:#fff

style ZIGBEE fill:#E67E22,stroke:#2C3E50,color:#fff

style CHOICE fill:#2C3E50,stroke:#16A085,color:#fff

WirelessHART’s TDMA and channel hopping provide deterministic, industrial-grade reliability required for process control. Zigbee’s CSMA/CA is suitable for non-critical monitoring but cannot guarantee timing for control loops.

WirelessHART uses graph routing where the Network Manager precomputes multiple paths for each device-to-gateway communication. Each device has at least two graphs (primary and backup). If a link fails, packets automatically follow the backup graph without requiring discovery protocols, achieving <100ms failover.

A typical WirelessHART deployment includes field devices (sensors, actuators), adapters (for retrofitting wired HART devices), the Gateway (protocol conversion), Network Manager (centralized controller), and Access Points (for extended coverage). The Network Manager maintains global knowledge of network topology and computes optimal TDMA schedules.

1001.4.1 Protocol Stack Overview

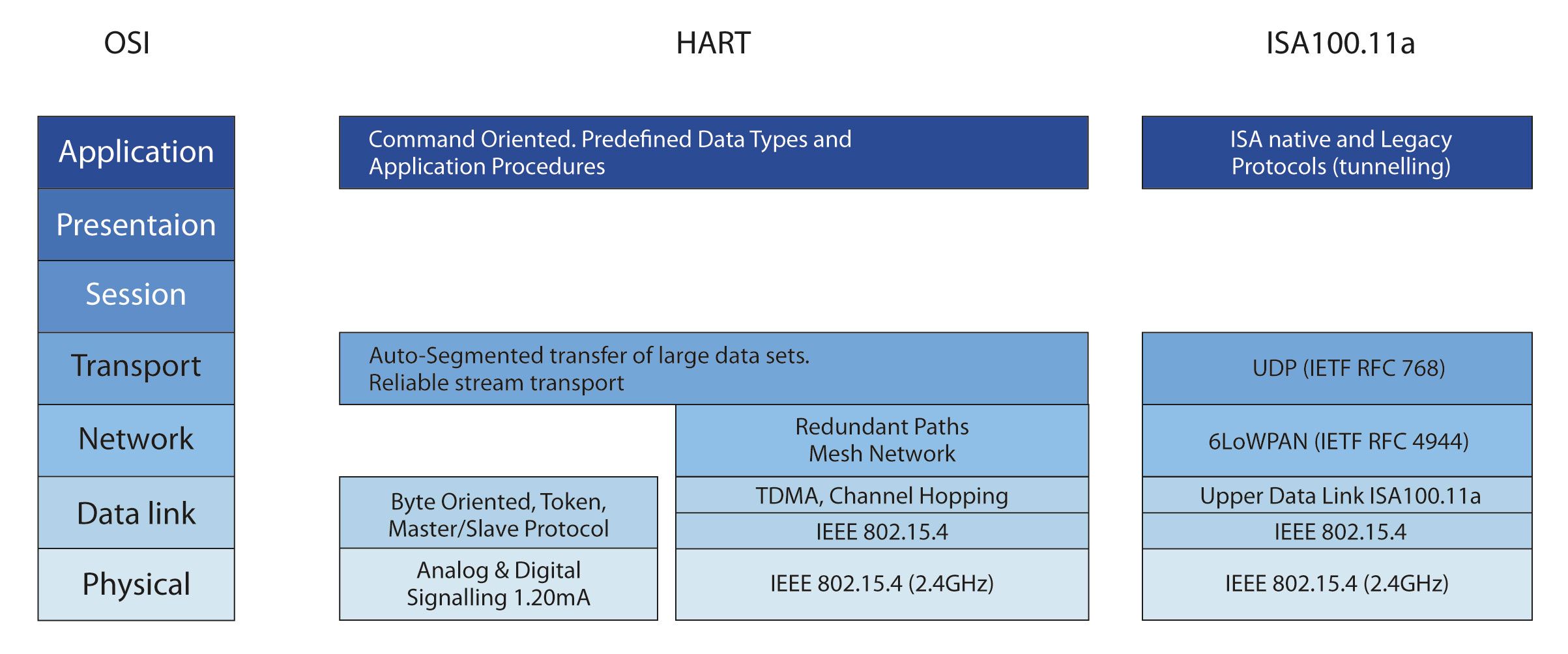

WirelessHART Protocol Stack: - Physical: IEEE 802.15.4 (2.4 GHz, O-QPSK, 15 channels) - Data Link: TDMA, superframes, channel hopping - Network: Graph routing, source routing, mesh - Transport: End-to-end reliability - Application: HART command set (compatible with wired HART)

1001.5 Knowledge Check

1001.6 Summary

WirelessHART fundamentals and architecture provide the foundation for understanding industrial wireless mesh networking:

- HART Heritage: WirelessHART extends the proven HART protocol (30+ million installed devices) to wireless, maintaining backward compatibility with existing industrial infrastructure

- Protocol Stack: Uses IEEE 802.15.4 physical layer at 2.4 GHz with a TDMA-based data link layer, graph routing at the network layer, and the standard HART command set at the application layer

- Key Components: Gateway (bridges wireless to plant backbone), Network Manager (centralized control), field devices (sensors/actuators), and adapters (for wired HART retrofit)

- Design Goals: Industrial-grade reliability (99.999%), deterministic latency (<100ms), self-healing mesh, and secure communication

- Cost Benefits: Wireless deployment can reduce installation costs by 80% compared to wired solutions, especially in retrofit applications

1001.7 What’s Next

Continue with the detailed technical mechanisms that enable WirelessHART’s reliability:

- Next Chapter: WirelessHART TDMA and Channel Hopping - Deep dive into time-synchronized communication and frequency diversity

- Compare: Zigbee - Understand how Zigbee differs from WirelessHART for building and home automation

- Related: ISA 100.11A - Learn about the competing industrial wireless standard with IPv6/6LoWPAN integration