213 Processes & Systems: Core Definitions

213.1 Learning Objectives

By the end of this chapter, you will be able to:

- Define Process Concepts: Explain systems, processes, and input-output transformations in IoT

- Understand Block Diagrams: Represent complex electronic systems as interconnected components

- Decompose IoT Systems: Break down IoT systems into hardware, software, and network subsystems

- Analyze System Components: Identify inputs, outputs, processes, and constraints in IoT devices

- Apply Hierarchical Design: Use modular decomposition for debugging and optimization

213.2 Prerequisites

Before diving into this chapter, you should be familiar with:

- Sensor Fundamentals and Types: Understanding how sensors measure physical phenomena is essential for grasping how systems transform inputs into meaningful data

- Actuators: Knowledge of actuators helps understand how systems produce physical outputs in response to control signals

- IoT Reference Models: Familiarity with layered IoT architectures provides context for where processes operate within the device-to-cloud stack

213.3 Getting Started (For Beginners)

TipWhat Are Processes and Systems? (Simple Explanation)

Analogy: A process is like following a recipe—you have ingredients (inputs), cooking steps (the process), and a finished dish (output). A system is the entire kitchen setup that makes cooking possible.

Simple explanation: - Process: Any action that transforms inputs into outputs - System: A collection of parts working together toward a goal - Control: How you adjust the process to get the desired output

213.3.1 The Kitchen Analogy

NoteUnderstanding Systems Through Cooking

KITCHEN (System) - Baking a Cake:

| Component | Role | Examples |

|---|---|---|

| INPUTS | Raw materials & energy | Eggs, Milk, Flour, Butter, Electricity |

| PROCESS | Transformation | Mixing & Baking |

| OUTPUT | End product | Cake |

| CONTROL | Regulation | Temperature Setting |

Flow: INPUTS → PROCESS → OUTPUT (with CONTROL regulating the process)

Key insight: The temperature dial is your “control”—you adjust it to get the right output!

213.3.2 Self-Check Questions

Before diving into the technical details, test your understanding:

- Basic Concept: What’s the difference between a process and a system?

- Answer: A process is the transformation (input → output). A system is everything that makes it work together.

- Real-World: Can you identify the inputs, process, and outputs of a smart light bulb?

- Answer: Input: power + command signal. Process: interpret command, adjust LED driver. Output: light at specified brightness/color.

NoteKey Takeaway

In one sentence: Systems are collections of components that work together, while processes are the transformations that systems perform on inputs to produce outputs.

Remember this: Every IoT device can be analyzed as a system with inputs (sensors, user commands), processes (algorithms, logic), and outputs (actuators, displays, data).

213.4 What is a Process and What is a System?

⭐ Difficulty: Foundational

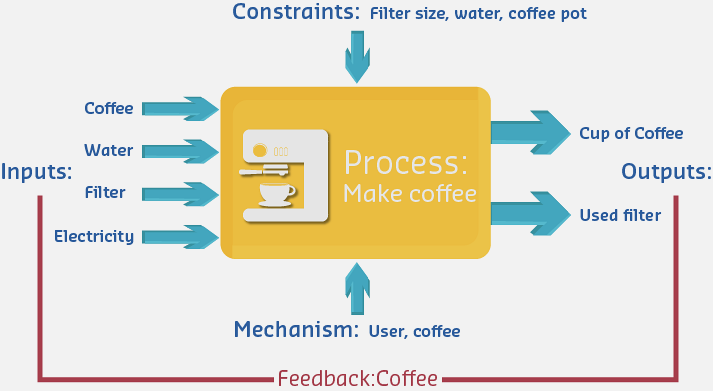

Most electronic systems, particularly IoT devices, are designed to perform specific tasks. These can be broken down into two fundamental components: the process and the system.

213.5 Key Definitions

- Process

- A series of actions or steps taken to achieve a particular end. In IoT devices, this is typically implemented by the program running on the microcontroller. The process defines how the device accomplishes its goal.

- System

- A set of things working together as parts of a mechanism or interconnecting network; a complex whole. In IoT, a system comprises the microcontroller, sensors, actuators, and their interactions working together to perform a specific function.

An electronic system is a physical interconnection of components that gathers information, processes it, and produces output. The sensors provide input, actuators provide output, and the microcontroller executes the process that transforms inputs into outputs.

Alternative View:

%%{init: {'theme': 'base', 'themeVariables': { 'primaryColor': '#2C3E50', 'primaryTextColor': '#fff', 'primaryBorderColor': '#16A085', 'lineColor': '#16A085', 'secondaryColor': '#E67E22', 'tertiaryColor': '#7F8C8D'}}}%%

flowchart TD

START([System Receives<br/>Input Signal]) --> SENSE[Sensor Layer<br/>Measure physical value]

SENSE --> CONVERT{Valid<br/>Reading?}

CONVERT -->|Yes| PROCESS[Processing Layer<br/>Execute algorithm]

CONVERT -->|No/Error| RETRY[Retry or<br/>Use default]

RETRY --> SENSE

PROCESS --> DECIDE{Output<br/>Required?}

DECIDE -->|Yes| ACTUATE[Actuation Layer<br/>Drive output device]

DECIDE -->|No change needed| WAIT[Wait for<br/>next cycle]

ACTUATE --> FEEDBACK{Closed-Loop<br/>System?}

FEEDBACK -->|Yes| MEASURE[Measure Output<br/>Compare to setpoint]

FEEDBACK -->|No| COMPLETE([Cycle Complete])

MEASURE --> ADJUST{Error<br/>Acceptable?}

ADJUST -->|No| PROCESS

ADJUST -->|Yes| COMPLETE

WAIT --> START

style START fill:#16A085,color:#fff

style SENSE fill:#2C3E50,color:#fff

style PROCESS fill:#2C3E50,color:#fff

style ACTUATE fill:#E67E22,color:#fff

style COMPLETE fill:#16A085,color:#fff

style MEASURE fill:#7F8C8D,color:#fff

%%{init: {'theme': 'base', 'themeVariables': { 'primaryColor': '#2C3E50', 'primaryTextColor': '#fff', 'primaryBorderColor': '#16A085', 'lineColor': '#16A085', 'secondaryColor': '#E67E22', 'tertiaryColor': '#7F8C8D'}}}%%

graph TB

subgraph Physical["Physical Layer"]

direction LR

ENV[Environment<br/>Temperature, Motion, Light]

ACT[Physical Actions<br/>Movement, Heat, Sound]

end

subgraph Sensing["Sensing Layer"]

direction LR

SENS[Sensors<br/>Convert physical to electrical]

TRANS[Transducers<br/>Signal conditioning]

end

subgraph Processing["Processing Layer"]

direction LR

ADC[ADC<br/>Analog to Digital]

MCU[Microcontroller<br/>Algorithm execution]

DAC[DAC<br/>Digital to Analog]

end

subgraph Control["Control Layer"]

direction LR

LOGIC[Control Logic<br/>Decision making]

STATE[State Machine<br/>Mode management]

end

subgraph Actuation["Actuation Layer"]

direction LR

DRV[Drivers<br/>Power amplification]

ACTS[Actuators<br/>Motors, valves, heaters]

end

ENV --> SENS

SENS --> TRANS

TRANS --> ADC

ADC --> MCU

MCU --> LOGIC

LOGIC --> STATE

STATE --> DAC

DAC --> DRV

DRV --> ACTS

ACTS --> ACT

ACT -.->|Feedback| ENV

style Physical fill:#7F8C8D,color:#fff

style Sensing fill:#16A085,color:#fff

style Processing fill:#2C3E50,color:#fff

style Control fill:#E67E22,color:#fff

style Actuation fill:#16A085,color:#fff

213.6 Block Diagram Representation

⭐ Difficulty: Foundational

Complex electronic systems can be represented as interconnected “black boxes” where each box represents an individual component or subsystem. This block-diagram representation allows us to analyze systems at different levels of abstraction without getting overwhelmed by implementation details.

213.7 IoT System Decomposition

⭐⭐ Difficulty: Intermediate

Modern IoT systems can be decomposed into hierarchical blocks at multiple levels:

This hierarchical view helps engineers: - Identify component boundaries and interfaces - Isolate problems during debugging - Design modular, reusable subsystems - Optimize specific subsystem performance

TipCross-Hub Connections

Interactive Learning Tools: - Simulations Hub - Try the Network Topology Explorer to visualize how processes flow through different system architectures - Videos Hub - Watch process control demonstrations showing real systems in action - Quizzes Hub - Test your understanding of system decomposition and component interactions

Knowledge Resources: - Knowledge Gaps Hub - Common misconceptions about systems vs processes explained - Knowledge Map - See how processes & systems connect to sensors, actuators, and architectures

NoteRelated Chapters

This Series: - Processes & Systems: Control Types - Open-loop vs closed-loop control - Processes & Systems: PID Control - PID controller theory and applications

Deep Dives: - Process Control and PID - Advanced feedback control systems - Processes Labs and Review - Hands-on implementations

Foundation: - IoT Reference Models - System architecture layers - Architectural Enablers - IoT technology stack

Sensing & Actuation: - Sensor Fundamentals - Input devices - Actuators - Output devices

213.8 Summary

This chapter covered the core definitions of processes and systems in IoT:

- System Definition: Understanding systems as collections of interacting components that transform inputs into outputs with defined boundaries

- Process Definition: Recognizing processes as series of actions or steps that add value by transforming inputs (materials, energy, information) into outputs

- Block Diagram Representation: Using abstraction to represent complex IoT systems as interconnected black boxes for analysis at multiple levels

- Hierarchical Decomposition: Breaking down IoT systems into hardware, software, and network subsystems for modular design and debugging

- Input-Output Transformations: Analyzing how electronic systems gather information through sensors, process it via microcontrollers, and produce outputs through actuators

- Design Considerations: Evaluating input validation, process robustness, output verification, error propagation, and resource constraints

213.9 What’s Next

The next chapter explores Control Types: Open-Loop vs Closed-Loop, introducing the fundamental distinction between systems that operate without feedback and those that continuously measure and adjust based on output. You’ll learn how feedback mechanisms enable systems to self-regulate and maintain desired behaviors automatically.