214 Processes & Systems: Control Types

214.1 Learning Objectives

By the end of this chapter, you will be able to:

- Compare Control Types: Differentiate between open-loop and closed-loop control systems

- Analyze Feedback Loops: Describe how feedback mechanisms maintain system stability

- Understand System Stability: Evaluate trade-offs between different control strategies for IoT

- Implement Self-Regulation: Build systems that automatically adjust to maintain desired behavior

- Apply Control Concepts: Select appropriate control strategies for different IoT scenarios

214.2 Prerequisites

Before diving into this chapter, you should be familiar with:

- Processes & Systems: Core Definitions: Understanding system decomposition and input-output transformations

- Sensor Fundamentals and Types: How sensors measure physical phenomena for feedback

- Actuators: How actuators produce physical outputs in response to control signals

214.3 Getting Started (For Beginners)

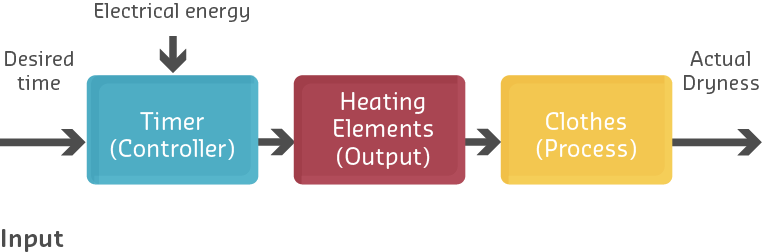

TipOpen-Loop vs Closed-Loop: The Core Concept

This is the most important concept in control systems:

| Type | How It Works | Example | Problem |

|---|---|---|---|

| Open-Loop | Set it and forget it | Toaster with timer | Burns toast if bread is thick |

| Closed-Loop | Continuously adjusts based on feedback | Thermostat | More complex, more reliable |

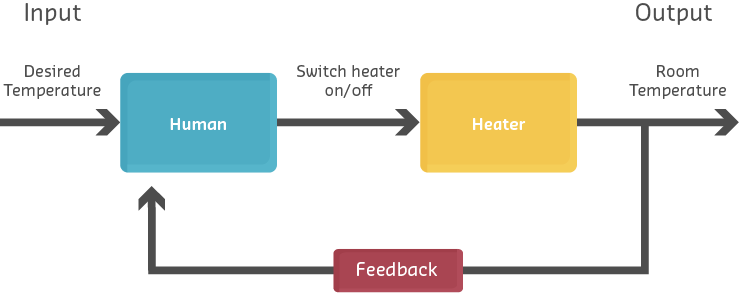

214.3.1 Real-World Comparison

Control System Comparison:

| Type | Device | Command | Behavior | Result |

|---|---|---|---|---|

| OPEN-LOOP (Dumb) | Space Heater | “Run for 2 hours” | Runs regardless of temperature | Maybe too hot or cold! |

| CLOSED-LOOP (Smart) | Smart Thermostat | “Keep room at 22°C” | Checks actual temp and adjusts | Always comfortable! |

214.3.2 Feedback Loop Explained

NoteThe Shower Temperature Problem

Everyone has experienced this control system:

Goal: Get water at perfect temperature (38°C)

| Step | Component | Action |

|---|---|---|

| 1 | Desired Temp (Setpoint) | You want 38°C |

| 2 | Valve (Actuator) | Turn valve to adjust |

| 3 | Water Temp (Output) | Water comes out |

| 4 | Your Hand (Sensor) | Feel water temperature |

| 5 | Feedback Loop | Compare to desired → Adjust valve → Repeat! |

This is a CLOSED-LOOP control system—you are the controller!

214.3.3 IoT Examples of Control Systems

Example 1: Smart Irrigation

Smart Irrigation Comparison:

| Type | Behavior | Problem/Benefit |

|---|---|---|

| OPEN-LOOP (Basic Timer) | Water lawn every day at 6 AM for 30 minutes | Waters even when it rained yesterday! |

| CLOSED-LOOP (Smart) | Moisture Sensor → Controller → Sprinkler Valve → Soil wetter → Feedback | Only waters when soil is actually dry! Saves 30-50% water |

Example 2: Smart HVAC

Smart HVAC Control System:

| Component | Details |

|---|---|

| INPUTS | Temperature, Humidity, Occupancy, Time of day, Energy price |

| PROCESS | HVAC Controller |

| OUTPUT | Comfortable Room! |

| FEEDBACK | Sensors report actual conditions back to controller |

Flow: INPUTS → PROCESS → OUTPUT → FEEDBACK → (back to PROCESS)

NoteKey Takeaway

In one sentence: Closed-loop control systems that measure output and adjust inputs automatically are the foundation of smart IoT - turning “dumb” timers into intelligent devices that respond to real conditions.

Remember this: If your IoT device just runs a timer without checking actual results, it is open-loop and will fail when conditions change - add a sensor and feedback to make it smart.

214.4 Feedback Control Systems in IoT

⭐⭐ Difficulty: Intermediate

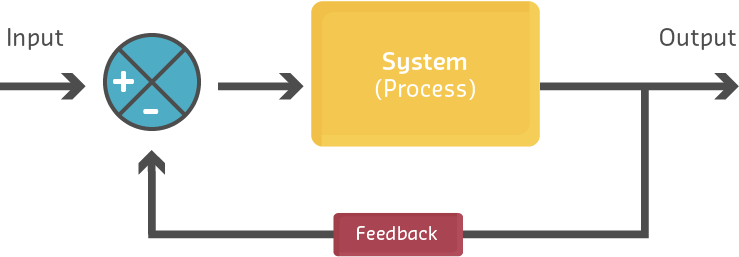

Understanding feedback control systems is essential for IoT device design. Most IoT applications require systems that can automatically maintain desired states without constant human intervention—this is the domain of closed-loop control.

214.5 Open-Loop vs Closed-Loop Systems

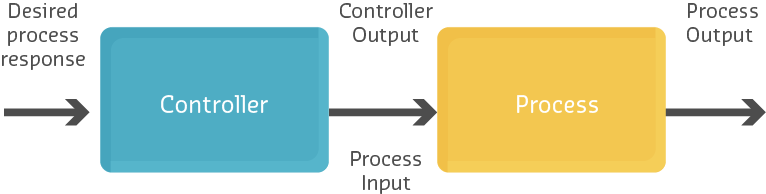

The fundamental distinction in control systems is whether they use feedback to adjust their behavior:

Detailed Comparison:

| Feature | Open-Loop | Closed-Loop |

|---|---|---|

| Feedback | None—operates based on predetermined inputs | Continuous—measures output and adjusts |

| Accuracy | Low—cannot correct for disturbances | High—self-corrects to maintain setpoint |

| Complexity | Simple—fewer components, easier to design | More complex—requires sensors and control logic |

| Cost | Lower—no sensor feedback required | Higher—additional sensors and processing |

| Reliability | Susceptible to drift and external changes | Robust to disturbances and component variations |

| Speed | Can be fast (no feedback delays) | Slower (must wait for feedback measurements) |

| Energy | Less power (no continuous sensing) | More power (continuous sensing and adjustment) |

| IoT Example | Timer-based irrigation (waters for fixed duration) | Soil moisture-based irrigation (waters until target moisture reached) |

| Use Case | Predictable environments, low criticality | Variable environments, high accuracy needs |

Real-World Examples:

Key Insight: Open-loop systems are predictable but inflexible—they cannot adapt to changing conditions. Closed-loop systems are adaptive but require more resources (sensors, processing, energy).

214.6 Real-World Example: Smart Factory Temperature Control

⭐⭐ Difficulty: Intermediate

Industry Context: A semiconductor manufacturing facility requires precise temperature control in clean rooms to maintain product quality. Even ±0.5°C variations can cause $50,000+ in defective wafer batches.

System Components:

| Component | Specification | Cost | Function |

|---|---|---|---|

| Temperature Sensors | ±0.1°C accuracy, PT1000 RTD | $85 each × 12 | Measure zone temperatures |

| HVAC Actuators | Modulating dampers, 0-10V control | $450 each × 4 | Regulate airflow |

| Edge Controller | Siemens S7-1200 PLC | $800 | Execute PID control loops |

| Cloud Dashboard | Azure IoT Central | $200/month | Monitoring and analytics |

Process Flow:

%%{init: {'theme': 'base', 'themeVariables': { 'primaryColor': '#2C3E50', 'primaryTextColor': '#fff', 'primaryBorderColor': '#16A085', 'lineColor': '#16A085', 'secondaryColor': '#E67E22', 'tertiaryColor': '#7F8C8D'}}}%%

flowchart TB

subgraph Inputs[Clean Room Inputs]

T1[Ambient Temperature]

H1[Heat from Equipment]

P1[Worker Body Heat]

A1[HVAC Supply Air]

end

subgraph Process[Control Process - Edge PLC]

S1[Read 12 Temp Sensors]

C1[Calculate Zone Errors]

P2[PID Controller<br/>Kp=3.5, Ki=0.2, Kd=1.2]

O1[Output to Dampers]

end

subgraph Outputs[Controlled Outputs]

R1[Room Temp: 22.0 C +/- 0.1 C]

Q1[Product Quality: 99.7%]

E1[Energy: 12 kWh/hr]

end

subgraph Feedback[Feedback Loop]

M1[Measure Every 5 Seconds]

Compare[Compare to 22.0 C Setpoint]

end

Inputs --> S1

S1 --> C1

C1 --> P2

P2 --> O1

O1 --> Outputs

Outputs --> M1

M1 --> Compare

Compare --> C1

style Inputs fill:#2C3E50,color:#fff

style Process fill:#E67E22,color:#fff

style Outputs fill:#16A085,color:#fff

style Feedback fill:#7F8C8D,color:#fff

Performance Metrics (Before vs After Closed-Loop Implementation):

| Metric | Before (Manual Control) | After (Closed-Loop Control) | Improvement |

|---|---|---|---|

| Temperature Stability | ±1.2°C variation | ±0.08°C variation | 93% reduction |

| Defect Rate | 3.2% (640 defects/20k wafers) | 0.3% (60 defects/20k wafers) | 91% reduction |

| Annual Defect Cost | $960,000 ($1,500/defect) | $90,000 | $870K saved |

| Energy Consumption | 15.2 kWh/hr (over-cooling) | 12.0 kWh/hr (optimized) | 21% reduction |

| Response to Disturbance | 12 minutes to stabilize | 3 minutes to stabilize | 75% faster |

| Operator Interventions | 8 adjustments/shift | 0.5 adjustments/shift | 94% reduction |

Key Insights:

Local Feedback is Critical: Edge PLC responds in <200ms. Cloud-only control would have 2-5 second latency—unacceptable for 5-second disturbances (door openings, equipment cycling).

System Decomposition: Clean separation of sensing (PT1000 RTDs), processing (PLC control algorithm), actuation (modulating dampers), and monitoring (Azure cloud) enabled modular upgrades without full replacement.

ROI Analysis: $12,220 total investment ($1,020 sensors + $1,800 actuators + $800 PLC + $600 cloud/3 months). Payback in 15 days from defect reduction alone ($870K annual savings ÷ 365 days = $2,384/day).

Feedback >> Open-Loop: Manual control (effectively open-loop with slow human feedback) caused ±1.2°C swings. Continuous sensor feedback reduced this to ±0.08°C—a 15× improvement.

214.7 Closed-Loop IoT System Diagram

Here’s a complete closed-loop control system architecture applied to an IoT smart thermostat:

System Operation:

- Setpoint: User sets desired temperature (22°C) via app or thermostat dial

- Comparison: Summing junction compares setpoint to measured temperature from sensor

- Error Calculation: If room is 18°C, error = 22°C - 18°C = +4°C (too cold)

- Controller: Calculates control signal based on error magnitude

- Actuator: HVAC system adjusts heating/cooling power based on control signal

- Process: Room temperature changes due to HVAC output

- Sensor: Thermometer measures actual room temperature

- Feedback: Measured temperature fed back to summing junction → loop repeats

Continuous Cycle: This loop executes continuously (e.g., every 30 seconds) to automatically maintain 22°C despite disturbances (door openings, sunlight, occupancy changes).

%%{init: {'theme': 'base', 'themeVariables': {'primaryColor': '#2C3E50', 'primaryTextColor': '#fff', 'lineColor': '#16A085', 'secondaryColor': '#E67E22', 'tertiaryColor': '#7F8C8D'}}}%%

graph TB

subgraph OpenLoop["OPEN-LOOP CONTROL"]

OL_IN[User Input<br/>Run for 2 hours]

OL_CTRL[Timer Controller]

OL_ACT[Heater]

OL_OUT[Room Temp<br/>Unknown result]

OL_IN --> OL_CTRL

OL_CTRL --> OL_ACT

OL_ACT --> OL_OUT

OL_PROB[Problem: No adaptation<br/>May overheat or underheat]

end

subgraph ClosedLoop["CLOSED-LOOP CONTROL"]

CL_SP[Setpoint<br/>22 C target]

CL_SUM((Compare))

CL_CTRL[Controller]

CL_ACT[HVAC System]

CL_PROC[Room]

CL_OUT[Actual Temp<br/>Measured result]

CL_SENS[Sensor]

CL_SP --> CL_SUM

CL_SUM --> CL_CTRL

CL_CTRL --> CL_ACT

CL_ACT --> CL_PROC

CL_PROC --> CL_OUT

CL_OUT --> CL_SENS

CL_SENS -->|Feedback| CL_SUM

CL_BEN[Benefit: Self-adjusting<br/>Maintains 22 C automatically]

end

style OL_IN fill:#7F8C8D,color:#fff

style OL_CTRL fill:#7F8C8D,color:#fff

style OL_OUT fill:#E74C3C,color:#fff

style OL_PROB fill:#E74C3C,color:#fff

style CL_SP fill:#16A085,color:#fff

style CL_SUM fill:#7F8C8D,color:#fff

style CL_CTRL fill:#2C3E50,color:#fff

style CL_OUT fill:#16A085,color:#fff

style CL_SENS fill:#E67E22,color:#fff

style CL_BEN fill:#16A085,color:#fff

CautionCommon Misconception: “More Feedback = Better Control”

Misconception: Adding more feedback loops and faster sampling rates always improves system performance.

Reality: Excessive feedback can cause instability, noise amplification, and wasted energy:

Problem 1: Too-Fast Feedback (Oversampling) - Example: Smart thermostat checking temperature every 100ms - Issue: HVAC systems have thermal inertia (heating takes 5-10 minutes) - Result: Controller sees no change → increases heating → overshoots → oscillates - Fix: Match sampling rate to system dynamics (check every 30-60 seconds)

Problem 2: Sensor Noise Amplification - Example: Soil moisture sensor with ±5% noise, sampled every second - Issue: Small noise fluctuations trigger irrigation on/off rapidly - Result: Valve wear, energy waste, inconsistent watering - Fix: Add moving average filter (average last 10 readings) before control decision

Problem 3: Cascaded Loops Instability - Example: Temperature controller → valve controller → motor controller - Issue: Each loop tries to “correct” the others’ actions - Result: System hunts/oscillates, never settles to stable state - Fix: Use hierarchical control with proper time-scale separation (outer loop 10× slower than inner)

Best Practices: - Match feedback rate to process dynamics: Slow systems (temperature) = slow feedback (10-60s), Fast systems (motor position) = fast feedback (1-10ms) - Filter sensor noise: Use moving average, median filter, or low-pass filter before control logic - Tune gains carefully: Start conservative (low gains), increase until system responds quickly without oscillation - Consider energy: Each sensor reading costs power—sample only as often as needed

Real IoT Example - Smart Irrigation: - Bad: Check soil moisture every 1 minute, water when <30% - Good: Check every 30 minutes (averaged over 5 readings), water when <25% for 3 consecutive checks

Rule of Thumb: Feedback interval should be 5-10× faster than the system’s settling time, but no faster (diminishing returns + wasted energy).

TipCross-Hub Connections

Interactive Learning Tools: - Simulations Hub - Try control system simulations to see feedback loops in action - Videos Hub - Watch process control demonstrations showing real controllers, feedback loops, and system stability concepts in action - Quizzes Hub - Test your understanding of open-loop vs closed-loop systems and feedback mechanisms

Knowledge Resources: - Knowledge Gaps Hub - Common misconceptions about control systems and feedback loops - Knowledge Map - See how control types connect to sensors, actuators, and system architecture

NoteRelated Chapters

This Series: - Processes & Systems: Core Definitions - What are processes and systems - Processes & Systems: PID Control - PID controller theory and applications

Deep Dives: - Process Control and PID - Advanced feedback control systems - Processes Labs and Review - Hands-on implementations

Foundation: - IoT Reference Models - System architecture layers - Architectural Enablers - IoT technology stack

Sensing & Actuation: - Sensor Fundamentals - Input devices - Actuators - Output devices

214.8 Summary

This chapter covered the fundamentals of control types in IoT systems:

- Open-Loop vs Closed-Loop Control: Distinguishing between systems that operate without feedback (open-loop) and those that continuously measure and adjust based on output (closed-loop)

- Feedback Control Systems: Understanding how closed-loop systems use sensors to measure outputs, compare to desired setpoints, and adjust actuators to maintain target behavior

- Error Signal Calculation: Learning how error = setpoint - measured value determines control direction and magnitude

- System Stability: Recognizing that feedback must be matched to system dynamics to avoid oscillations and instability

- Noise and Filtering: Understanding that sensor noise requires filtering before use in control decisions

- Real-World Applications: Applying control concepts to smart factory temperature control, irrigation systems, and HVAC automation

- Design Trade-offs: Evaluating accuracy vs complexity, cost vs reliability, and speed vs energy consumption

214.9 What’s Next

The next chapter explores PID Control for IoT, diving deep into Proportional-Integral-Derivative (PID) control theory, the mathematical foundation for feedback systems. You’ll learn how to tune PID controllers for stability, analyze system response curves, and implement control algorithms for real IoT applications like temperature regulation and motor control.