%%{init: {'theme': 'base', 'themeVariables': { 'primaryColor': '#2C3E50', 'primaryTextColor': '#fff', 'primaryBorderColor': '#16A085', 'lineColor': '#16A085', 'secondaryColor': '#E67E22', 'tertiaryColor': '#ecf0f1', 'fontSize': '16px'}}}%%

flowchart LR

A["User Flips<br/>Switch ON"] --> B["Switch<br/>Sensor<br/>Detects ON"]

B --> C["Microcontroller<br/>Processes"]

C --> D["Servo Motor<br/>Activates"]

D --> E["Mechanical Arm<br/>Flips Switch OFF"]

E -.->|Feedback Loop| B

style A fill:#7F8C8D,stroke:#2C3E50,stroke-width:2px,color:#fff

style B fill:#2C3E50,stroke:#16A085,stroke-width:2px,color:#fff

style C fill:#E67E22,stroke:#16A085,stroke-width:2px,color:#fff

style D fill:#E67E22,stroke:#16A085,stroke-width:2px,color:#fff

style E fill:#16A085,stroke:#2C3E50,stroke-width:2px,color:#fff

211 Processes and Systems: Feedback Mechanisms

211.1 Feedback in Electronic Systems

⭐ Difficulty: Foundational

Core Concept: A feedback loop continuously measures output, compares it to a desired setpoint, and adjusts the input to minimize the difference - creating a self-correcting system that maintains stability without constant human intervention. Why It Matters: Feedback transforms “dumb” devices into smart systems - a simple heater becomes a thermostat, a motor becomes a servo, and an irrigation pump becomes a precision agriculture system. Key Takeaway: The key components are: sensor (measures output), comparator (calculates error), controller (decides action), and actuator (makes changes) - break any link and the system loses its self-regulating ability.

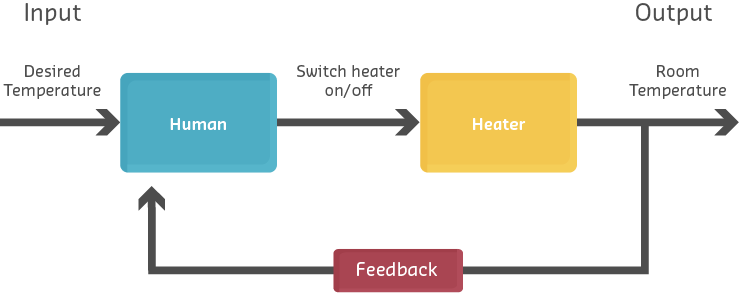

Feedback is a fundamental concept where a portion of the system’s output is routed back to influence the input. This creates a self-regulating mechanism that can improve system performance, stability, and accuracy.

211.1.1 Everyday Feedback Examples

We encounter feedback constantly in daily life:

- Thermostat: Room temperature (output) is measured and compared to the desired temperature (input), adjusting heating/cooling accordingly

- Cruise control: Vehicle speed (output) is monitored and throttle (input) is adjusted to maintain set speed

- Refrigerator: Internal temperature (output) controls compressor on/off cycles (input)

In IoT systems, feedback enables autonomous operation and adaptation to changing conditions.

211.1.2 Feedback in IoT Applications

IoT devices leverage feedback for various purposes:

- Environmental Control

- Smart thermostats, greenhouse automation, HVAC systems

- Process Monitoring

- Industrial sensors adjusting manufacturing parameters in real-time

- Safety Systems

- Automatic shutoffs when dangerous conditions detected

- Energy Management

- Battery monitoring systems adjusting charging rates

- Distributed Feedback

- Water quality monitoring where local sensors trigger remote actuators

%%{init: {'theme': 'base', 'themeVariables': { 'primaryColor': '#2C3E50', 'primaryTextColor': '#fff', 'primaryBorderColor': '#16A085', 'lineColor': '#16A085', 'secondaryColor': '#E67E22', 'tertiaryColor': '#ecf0f1', 'fontSize': '14px'}}}%%

graph TB

subgraph Edge ["Edge Devices"]

S1["Water Quality<br/>Sensor Node"]

A1["Aeration Pump<br/>Actuator Node"]

end

subgraph Cloud ["Cloud Layer"]

C1["IoT Platform<br/>Decision Engine"]

C2["Rule Engine:<br/>IF DO < 5mg/L<br/>THEN Activate Pump"]

C3["Data Storage<br/>& Analytics"]

end

S1 -->|Dissolved Oxygen<br/>Reading: 4.2 mg/L| C1

C1 --> C2

C2 -->|Evaluate Condition| C3

C2 -->|Send Command:<br/>Turn ON Pump| A1

A1 -->|Increase DO Level| Water["Water Body"]

Water -.->|Feedback: Measure<br/>New DO Level| S1

style S1 fill:#2C3E50,stroke:#16A085,stroke-width:2px,color:#fff

style A1 fill:#E67E22,stroke:#16A085,stroke-width:2px,color:#fff

style C1 fill:#16A085,stroke:#2C3E50,stroke-width:2px,color:#fff

style C2 fill:#E67E22,stroke:#16A085,stroke-width:2px,color:#fff

style Water fill:#7F8C8D,stroke:#2C3E50,stroke-width:2px,color:#fff

Distributed IoT Feedback System: Sensor nodes transmit water quality data to cloud platform, where rule engine evaluates conditions and sends commands to remote actuator nodes, creating a closed feedback loop across network boundaries.

This distributed feedback system demonstrates how IoT architectures can implement control loops across multiple devices and network boundaries, with cloud-based decision-making coordinating local sensor and actuator nodes.

211.2 Electronic Feedback Systems

⭐⭐ Difficulty: Intermediate

Feedback systems are classified based on whether they monitor and respond to their outputs. The two primary categories are closed-loop and open-loop systems, each with distinct characteristics and applications.

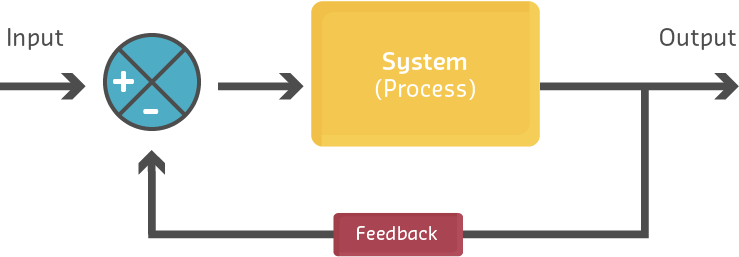

211.2.1 Closed-Loop Feedback Systems

In a closed-loop system, a portion of the output is fed back to the input and either added to (positive feedback) or subtracted from (negative feedback) the input signal. This creates a self-regulating system that continuously updates based on current output conditions.

%%{init: {'theme': 'base', 'themeVariables': { 'primaryColor': '#2C3E50', 'primaryTextColor': '#fff', 'primaryBorderColor': '#16A085', 'lineColor': '#16A085', 'secondaryColor': '#E67E22', 'tertiaryColor': '#ecf0f1', 'fontSize': '16px'}}}%%

graph LR

SP["Set Point<br/>Desired Value"] --> Comparator["⊖<br/>Comparator"]

Feedback["Feedback<br/>Sensor"] -->|Measured<br/>Output| Comparator

Comparator -->|Error Signal<br/>SP minus Measured| Controller["Controller"]

Controller -->|Control Signal| Process["Process/<br/>Plant"]

Process -->|Output| Output["System<br/>Output"]

Output -.->|Feedback Path| Feedback

style SP fill:#16A085,stroke:#2C3E50,stroke-width:2px,color:#fff

style Comparator fill:#E67E22,stroke:#16A085,stroke-width:3px,color:#fff

style Controller fill:#2C3E50,stroke:#16A085,stroke-width:2px,color:#fff

style Process fill:#7F8C8D,stroke:#16A085,stroke-width:2px,color:#fff

style Feedback fill:#2C3E50,stroke:#16A085,stroke-width:2px,color:#fff

style Output fill:#16A085,stroke:#2C3E50,stroke-width:2px,color:#fff

Closed-Loop Feedback System Block Diagram: Set point is compared with measured output, generating error signal. Controller processes error and adjusts system input. Feedback sensor creates continuous regulation loop.

Key Components:

- Set Point (SP): The desired target value

- Error Signal: Difference between set point and measured output

- Controller: Processes error and determines corrective action

- Process/Plant: The system being controlled

- Feedback Sensor: Measures actual output

- Comparator (Σ): Computes error = SP - measured value

Negative vs Positive Feedback:

%%{init: {'theme': 'base', 'themeVariables': { 'primaryColor': '#2C3E50', 'primaryTextColor': '#fff', 'primaryBorderColor': '#16A085', 'lineColor': '#16A085', 'secondaryColor': '#E67E22', 'tertiaryColor': '#ecf0f1', 'fontSize': '14px'}}}%%

graph TB

subgraph Negative ["Negative Feedback (Stabilizing)"]

N1["Setpoint:<br/>22°C"] --> N2["Error:<br/>+2°C too cold"]

N2 -->|Increase Heat| N3["Temperature<br/>Rises"]

N3 -->|Error Decreases| N4["Reduce Heat<br/>Output"]

N4 -.->|Approaches Target| N1

end

subgraph Positive ["Positive Feedback (Amplifying)"]

P1["Small Voltage<br/>Increase"] --> P2["Amplifier<br/>Gain x10"]

P2 -->|Output| P3["Larger Voltage"]

P3 -->|Feed Back| P2

P2 -.->|Continues<br/>Amplifying| P4["Saturates or<br/>Oscillates"]

end

style N1 fill:#16A085,stroke:#2C3E50,stroke-width:2px,color:#fff

style N2 fill:#E67E22,stroke:#16A085,stroke-width:2px,color:#fff

style N3 fill:#2C3E50,stroke:#16A085,stroke-width:2px,color:#fff

style N4 fill:#2C3E50,stroke:#16A085,stroke-width:2px,color:#fff

style P1 fill:#2C3E50,stroke:#16A085,stroke-width:2px,color:#fff

style P2 fill:#E67E22,stroke:#16A085,stroke-width:2px,color:#fff

style P3 fill:#16A085,stroke:#2C3E50,stroke-width:2px,color:#fff

style P4 fill:#E74C3C,stroke:#2C3E50,stroke-width:2px,color:#fff

Negative vs Positive Feedback Comparison: Negative feedback opposes changes to stabilize the system (thermostat reducing heat as temperature approaches target). Positive feedback amplifies changes, leading to runaway growth or oscillation.

Negative Feedback (most common in IoT): - Opposes changes from the set point - Provides stability and regulation - Example: Thermostat reducing heat as temperature approaches target

Positive Feedback (less common, specialized uses): - Reinforces changes from the set point - Can cause instability or rapid state changes - Example: Schmitt trigger with hysteresis for noise immunity

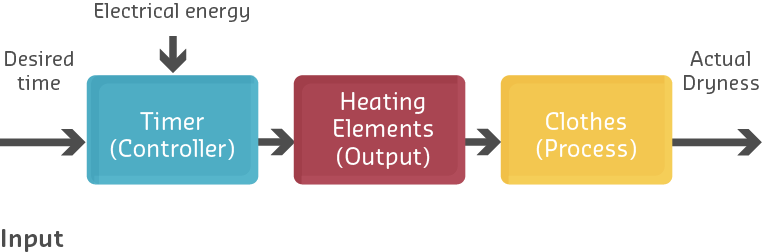

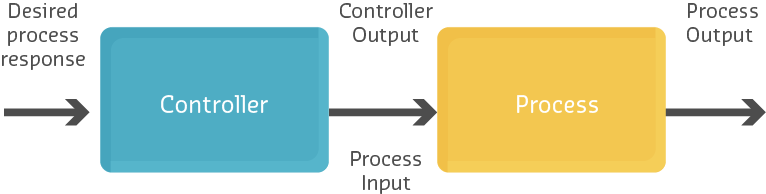

211.2.2 Open-Loop Control Systems

An open-loop system does not monitor or measure its output. It executes a predetermined action based solely on the input, without feedback. This is also called a non-feedback system.

%%{init: {'theme': 'base', 'themeVariables': { 'primaryColor': '#2C3E50', 'primaryTextColor': '#fff', 'primaryBorderColor': '#16A085', 'lineColor': '#16A085', 'secondaryColor': '#E67E22', 'tertiaryColor': '#ecf0f1', 'fontSize': '16px'}}}%%

graph LR

Input["Input<br/>(Set Timer<br/>60 min)"] --> Controller["Controller<br/>(Timer)"]

Controller -->|Run for<br/>60 minutes| Process["Process<br/>(Dryer)"]

Process -->|Unknown State| Output["Output<br/>(Clothes)"]

style Input fill:#16A085,stroke:#2C3E50,stroke-width:2px,color:#fff

style Controller fill:#2C3E50,stroke:#16A085,stroke-width:2px,color:#fff

style Process fill:#E67E22,stroke:#16A085,stroke-width:2px,color:#fff

style Output fill:#7F8C8D,stroke:#16A085,stroke-width:2px,color:#fff

Open-Loop System Block Diagram: Input (timer setting) determines controller action without measuring output state. System executes predetermined sequence with no knowledge of actual results (clothes may be over-dried or under-dried).

Characteristics:

- No feedback path from output to input

- Cannot self-correct for disturbances or errors

- Simpler and less expensive to implement

- Suitable when output is predictable and disturbances are minimal

211.3.1 Open-Loop in IoT Sensing Applications

Open-loop architectures are increasingly common in IoT data collection scenarios where:

- Device only senses and transmits data

- No local actuation required

- Analysis and decision-making occur remotely

- Feedback loop exists at system level, but not device level

%%{init: {'theme': 'base', 'themeVariables': { 'primaryColor': '#2C3E50', 'primaryTextColor': '#fff', 'primaryBorderColor': '#16A085', 'lineColor': '#16A085', 'secondaryColor': '#E67E22', 'tertiaryColor': '#ecf0f1', 'fontSize': '15px'}}}%%

flowchart TB

Sensor["Sensor Node<br/>(Open-Loop)"] -->|Periodic Data<br/>Transmission| Cloud["Cloud<br/>Platform"]

Sensor -->|Temp: 24°C<br/>Humidity: 65%| Cloud

Cloud -->|Store & Analyze| DB["Data<br/>Storage"]

Cloud -->|Dashboard| User["Human<br/>Operator"]

style Sensor fill:#2C3E50,stroke:#16A085,stroke-width:2px,color:#fff

style Cloud fill:#16A085,stroke:#2C3E50,stroke-width:2px,color:#fff

style DB fill:#7F8C8D,stroke:#16A085,stroke-width:2px,color:#fff

style User fill:#E67E22,stroke:#16A085,stroke-width:2px,color:#fff

IoT Sensor Node Open-Loop Data Collection: Device only senses and transmits data periodically without local actuation. No device-level feedback loop, but human operators or cloud systems may take action based on reported data.

Characteristics: - Node transmits sensor readings periodically - No local feedback or control - Simple, low power consumption - Suitable for remote monitoring applications

However, at the system level, there may be feedback:

%%{init: {'theme': 'base', 'themeVariables': { 'primaryColor': '#2C3E50', 'primaryTextColor': '#fff', 'primaryBorderColor': '#16A085', 'lineColor': '#16A085', 'secondaryColor': '#E67E22', 'tertiaryColor': '#ecf0f1', 'fontSize': '14px'}}}%%

graph TB

subgraph Edge ["Edge Devices (Open-Loop Individually)"]

S["Sensor Node:<br/>Measure Soil<br/>Moisture 25%"]

A["Actuator Node:<br/>Irrigation Valve"]

end

subgraph Cloud ["Cloud System (Closed-Loop Coordination)"]

P["IoT Platform"]

R["Rule: IF moisture<br/>< 30% THEN<br/>Activate Irrigation"]

D["Database &<br/>Analytics"]

end

S -->|Transmit:<br/>Moisture = 25%| P

P --> R

R -->|Evaluate| D

R -->|Command:<br/>Open Valve| A

A -->|Water Soil| Field["Field"]

Field -.->|Moisture Increases<br/>to 60%| S

style S fill:#2C3E50,stroke:#16A085,stroke-width:2px,color:#fff

style A fill:#E67E22,stroke:#16A085,stroke-width:2px,color:#fff

style P fill:#16A085,stroke:#2C3E50,stroke-width:2px,color:#fff

style R fill:#E67E22,stroke:#16A085,stroke-width:2px,color:#fff

style Field fill:#7F8C8D,stroke:#16A085,stroke-width:2px,color:#fff

System-Level Closed-Loop with Device-Level Open-Loop: Individual sensor and actuator nodes operate open-loop (no local feedback), but cloud platform creates system-level feedback by coordinating remote sensing and actuation based on rules.

This architecture demonstrates that while individual devices operate open-loop, the overall IoT system implements closed-loop control through cloud-based coordination.

Core Concept: Open-loop systems execute predetermined actions without measuring results (like a timer), while closed-loop systems continuously measure output and adjust to maintain desired state (like a thermostat). Why It Matters: Closed-loop costs more but adapts to disturbances - choose open-loop for predictable, cost-sensitive applications; choose closed-loop when accuracy matters more than simplicity. Key Takeaway: Ask yourself: “Will the environment change unpredictably?” If yes, use closed-loop. If the process is highly repeatable with minimal disturbances, open-loop may suffice and save cost.