100 Industry 4.0 and IoT Device Classification

100.1 Learning Objectives

By the end of this chapter, you will be able to:

- Trace industrial revolutions: Understand the progression from Industry 1.0 to 4.0

- Identify Industry 4.0 technologies: Recognize CPS, IoT, Big Data, and AI integration

- Classify IoT devices: Apply the classification framework (Embedded/Connected/IoT)

- Assess organizational maturity: Evaluate Industry 4.0 readiness

IoT Overview Series: - IoT Introduction - Getting started with IoT and the Five Verbs - Device Evolution - Embedded vs Connected vs IoT products - IoT Systems Evolution - Computing evolution enabling IoT

Industrial IoT Deep Dives: - Industrial IoT (IIoT) - Detailed IIoT applications - Application Domains - Industry-specific implementations

100.2 The Evolution of Industry 4.0

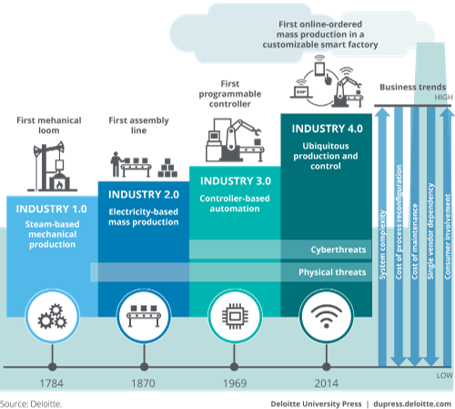

Industry 4.0, also known as the Fourth Industrial Revolution, is the latest phase in the transformation of manufacturing and industrial processes. It builds on three prior industrial revolutions, each characterized by technological advancements that fundamentally reshaped production methods. This revolution signifies the convergence of advanced technologies such as automation, connectivity, and data-driven decision-making, fundamentally reshaping production processes and supply chains.

This video provides an overview of the Fourth Industrial Revolution and how IoT, AI, and automation are transforming manufacturing.

100.2.1 Stages of Industrial Evolution

- Industry 1.0 (1784):

- Technological Advancement: Steam and water power revolutionized production, enabling mechanized manufacturing.

- Key Development: The first mechanical loom marked the transition from hand production to early factories.

- Industry 2.0 (1870):

- Technological Advancement: Electricity enabled mass production and the introduction of assembly lines.

- Key Development: This era saw significant productivity improvements and the rise of organized factory systems.

- Industry 3.0 (1969):

- Technological Advancement: The advent of computers and automation allowed factories to integrate programmable controllers.

- Key Development: Electronics and information technology began automating repetitive tasks, laying the groundwork for modern manufacturing.

- Industry 4.0 (2014):

- Technological Advancement: The integration of cyber-physical systems, IoT, big data, and artificial intelligence transformed production processes into highly interconnected ecosystems.

- Key Development: Smart factories emerged, characterized by real-time data exchange, predictive maintenance, and interconnected supply chains.

100.2.2 Defining Features of Industry 4.0

- Automation and Machine-to-Machine Communication (M2M):

- Industry 4.0 harnesses advanced automation systems and seamless communication between machines to improve efficiency and reduce the need for human intervention.

- Internet of Things (IoT):

- IoT devices embedded in industrial systems enable real-time monitoring, diagnostics, and predictive maintenance, creating more adaptive and responsive manufacturing environments.

- Smart Manufacturing:

- Industry 4.0 introduces smart factories where interconnected devices and systems streamline production, enhance quality control, and minimize waste.

- Big Data and Analytics:

- The massive volumes of data generated by connected systems are analyzed to derive actionable insights, enabling better decision-making and operational optimization.

- Cyber-Physical Systems (CPS):

- CPS integrate physical processes with digital technologies, enabling systems to monitor, learn, and optimize autonomously.

100.2.3 Applications and Use Cases

- Smart Factories: Customizing products at scale with efficiency.

- Predictive Maintenance: Using IoT sensors to identify potential equipment failures before they occur.

- Supply Chain Optimization: Enhancing logistics through real-time tracking and communication between supply chain components.

- Worker Safety: Employing wearable IoT devices to monitor and ensure worker safety in industrial environments.

100.2.4 Industry 4.0 Technologies

- Smart Machines: Sensors and networks that diagnose and resolve issues independently.

- Big Data: Utilizing extensive datasets for predictive insights and maintenance.

- Artificial Intelligence: Employing machine learning to enhance process efficiency and adaptability.

- Autonomous Systems: Drones, robots, and other autonomous entities transforming supply chains and manufacturing operations.

100.2.5 Benefits of Industry 4.0

- Enhanced Efficiency: Automated systems and advanced analytics optimize productivity and minimize downtime.

- Cost Savings: Streamlined operations reduce operational costs and resource waste.

- Sustainability: Smart technologies enable eco-friendly production practices and efficient resource management.

100.2.6 Preparing for Industry 4.0

Organizations must adapt to this new industrial paradigm by:

- Embracing Smart Technologies: Investing in IoT, AI, and advanced analytics to optimize operations.

- Reskilling the Workforce: Equipping employees with the knowledge to work alongside collaborative robots (cobots) and manage intelligent systems.

- Reevaluating Business Models: Transitioning from traditional approaches to innovative, tech-driven strategies.

Industry 4.0 represents more than a technological shift; it is a call for a systemic transformation in how industries operate, innovate, and deliver value. By integrating smart, connected technologies, businesses can remain competitive and sustainable in an increasingly connected world.

100.3 Understanding IoT Device Classification

One of the most important skills when learning IoT is being able to classify devices correctly. Not every “smart” device is truly IoT - understanding the differences helps you make better design decisions.

100.3.1 The Three Device Categories

This variant shows device classification as a decision tree - answer yes/no questions to classify any device:

Why this variant helps: The original shows three categories side-by-side with checkmarks. This decision tree shows the process of classification - you can follow it like a flowchart for any device you encounter. It’s actionable: pick up any device, answer three questions, and you’ll know its classification.

100.3.2 Practical Example: The Washing Machine

Let’s trace how the same appliance evolves through each category:

| Feature | Embedded | Connected | IoT |

|---|---|---|---|

| Example | Timer-based washer | Wi-Fi-enabled washer | Smart washer |

| Computation | Basic timer chip | Microcontroller | Processor + sensors |

| Internet | None | Wi-Fi for notifications | Cloud connectivity |

| Intelligence | Fixed programs | Remote control only | Learns your patterns |

| User Value | Washes clothes | Alerts when done | Optimizes water, energy, detergent |

Ask these three questions in order:

- Does it have a computer chip inside? -> If No, it’s just a mechanical device

- Can it connect to the internet? -> If No (even with a chip), it’s Embedded

- Does it make intelligent decisions from data? -> If No, it’s Connected; If Yes, it’s IoT

100.3.3 Real-World Classification Examples

| Device | Classification | Why? |

|---|---|---|

| Digital alarm clock | Embedded | Has chip, no internet |

| Basic smart plug | Connected | On/off via app, no intelligence |

| Nest thermostat | IoT | Learns schedule, optimizes energy |

| Fitness tracker (basic) | Connected | Syncs data, no analysis |

| Apple Watch | IoT | Health insights, fall detection |

| Wi-Fi light bulb | Connected | Remote control only |

| Philips Hue with routines | IoT | Adapts to patterns, integrates sensors |

100.3.4 Why Classification Matters

Understanding these categories helps you:

- As a consumer: Know what you’re actually buying (many “smart” devices are just connected)

- As a designer: Choose the right level of complexity for your product

- As an engineer: Select appropriate sensors, connectivity, and processing power

- For cost estimation: IoT devices require more development investment than connected devices

Try classifying these devices before checking the answers:

- A refrigerator with a digital temperature display

- A refrigerator that sends alerts when the door is left open

- A refrigerator that tracks food expiration and suggests recipes

Answers: 1. Embedded - Has computation (digital display), no internet 2. Connected - Has internet for alerts, but no intelligent decisions 3. IoT - Analyzes contents, makes recommendations, learns patterns

100.4 Knowledge Check

Test your understanding of IoT fundamentals with these questions.

100.5 Summary

In this chapter, you learned:

- Four industrial revolutions progressed from steam (1.0) to electricity (2.0) to computers (3.0) to IoT/AI (4.0)

- Industry 4.0 technologies include CPS, IoT, Big Data, and AI working together

- Device classification uses three categories: Embedded, Connected, and IoT

- Classification matters for purchasing decisions, design choices, and cost estimation

- Value increases exponentially from Embedded (basic) to Connected (convenience) to IoT (optimization)

100.6 What’s Next?

Continue to IoT Application Galleries to explore visual galleries of IoT applications across industries.